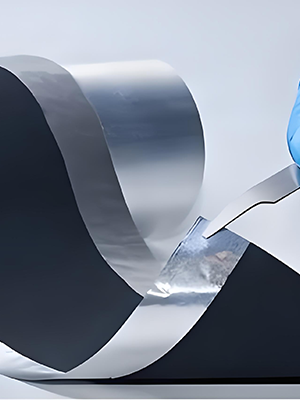

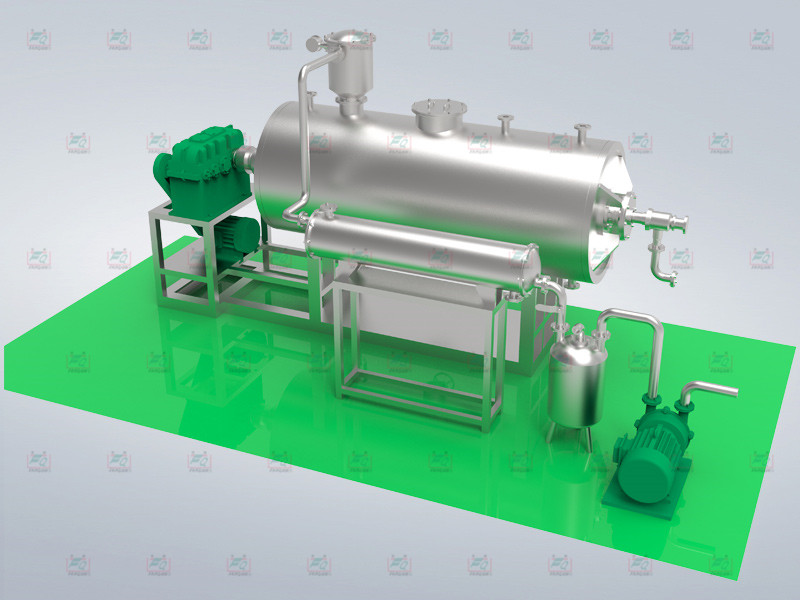

Fanqun Vacuum Rake Dryer specializes in gentle drying and solvent removal for heat-sensitive, viscous, or toxic materials. Its rotating rake arms with adjustable blades create a progressive mixing motion, ensuring uniform heat transfer under vacuum conditions (≤100 mbar). Ideal for pharmaceuticals (APIs, intermediates), agrochemical pastes, and specialty polymers, this dryer prevents material degradation through precise temperature control (20°C to 150°C). The jacketed body (316L stainless steel) and CIP/SIP compatibility meet GMP standards, while the integrated condenser achieves >98% solvent recovery efficiency for cost-effective operations.

Key Features:

Working Volume: 200L to 12,000L

Heating Media: Steam, thermal oil, or hot water

Safety: ATEX-certified models for explosive atmospheres, oxygen level monitoring

Applications: Dyes, battery slurries, herbal extracts, and silicone resins

Technical Highlights:

Dual Rake System: Primary rake for material advancement + secondary rake for wall cleaning.

Vacuum Stability: <1% pressure fluctuation with Hermetic seal technology.

Energy Efficiency: 30% lower steam consumption vs. conventional vacuum dryers.

The vacuum harrow drying equipment series of Jiangsu Fanqun Drying Equipment Factory Co., Ltd. includes ZB Series Vacuum Harrow Drying Equipment and PZG Harrow Dryer,Rake drying Equipment

Global Vacuum Rake Dryer Solutions | Drying Systems for Different Industries

Energy-Efficient, Customized Drying Equipment for Chemicals industry,Pharmaceutic industry, Food industry, Metallurgy and Minerals industry –

Trusted by 300+ Clients Worldwide

Vacuum Harrow Drying Equipment -

Drying Solutions for Multiple Industries

Food industry Processing soy protein, starch, seasonings, etc., to retain the nutrients and flavour of food, in line with health standards.

|

Pharmaceutical industry Rapid drying of drug raw materials, intermediates and excipients to ensure the purity and bioavailability of active ingredients and avoid degradation of heat-sensitive substances. |

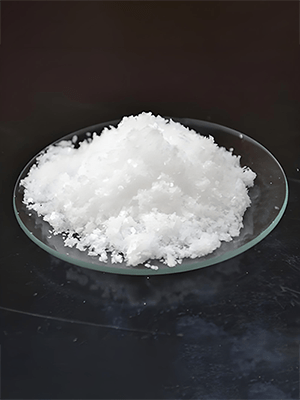

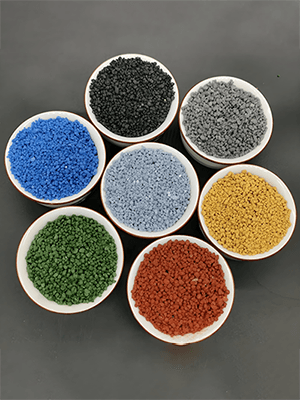

Chemical industry Used for drying inorganic salts (such as copper sulfate, iron oxide), organic acids, dyes, pigments, etc., to achieve efficient drying while maintaining chemical stability. |

Environmental Protection and Waste Treatment Industrial sludge, municipal sludge, organic wastewater extracts (e.g. proteins), biomass waste (wood chips, straw), etc. |

Ceramics and Minerals Drying kaolin, silica and other raw materials, to improve powder fluidity and sintering efficiency, to ensure the uniformity of particles. |

New Energy and Materials Science Polysilicon cutting fluid, lithium battery electrode material precursor, solar wafer waste, graphene composite materials, etc. |

| |

Advantages Of Our Vacuum Harrow Dryer |

|

| |

|

Thank them for their trust

Long-term partner of the world's and China's top 500 companies

| | | | |

| | | | |

Tailor-Made Journey for Your Vacuum Rake Drying Solution

Stage 1 | Precision Collaboration Workshop Carry out double-blind demand in-depth mining: led by senior drying processor, establish customised development matrix model through reverse analysis of material characteristics, energy consumption benchmarking, and historical case benchmarking. |

Stage 2 | Dynamic Thermodynamic Modelling Using multi-physical field coupling simulation technology to construct an exclusive drying dynamics model. Through the visualisation of airflow distribution simulation and heat transfer gradient prediction, the optimal combination of equipment structure parameters can be locked. |

Stage 3 | Lean Manufacturing Quality Chain Implementation of German VDI standard manufacturing protocols: open access to witness key points (e.g. verification of stainless steel welding process, airtightness testing of air ducts), support for customer representatives in modular pre-acceptance test (FAT). |

Stage 4 | Turnkey Integrated Systems Implementation of a ‘Zero Boundary’ delivery programme: including environmental adaptation (altitude/humidity compensation), thermal system balancing commissioning, and operational maintenance sandboxes to ensure production at design capacity. |

Stage 5 | Lifecycle Protection The IoT Remote Operation and Maintenance Centre is enabled to provide dynamic analysis of drying efficiency, preventive maintenance warnings, and process upgrading kit push, building a closed loop of continuous value-added intelligent manufacturing ecology. |

About Us

Jiangsu Fanqun Drying Equipment is a manufacturer of vacuum rake dryers,

customising a wide range of drying equipment for the high demands of the food, tobacco, chemical and pharmaceutical industries.

We are Fanqun Drying Equipment Factory | Forty years ago, China's drying equipment field was still blank, Mr Fan Bingxi sowed a seed of innovation in Zhenglu Town, Changzhou. From the first hot air circulation oven to the intelligent drying system, Fanqun drying with craftsmanship as the furnace, science and technology as the flame, quenching the benchmark of national industry.

As a pioneer in the industry, the company has accumulated more than 30 national patents, led the development of centrifugal spray drying tower, intelligent Chinese medicine extract dryer and other milestone products, breakthrough in Europe and the United States technology blockade, and twice undertook the national science and technology research projects. 2002 among the high-tech enterprises in Jiangsu Province, ‘Fanqun brand’ equipment is exported to more than 50 countries. Its ‘Fanqun brand’ equipment is exported to more than 50 countries, and is praised by the American chemical giants for its ‘performance exceeding the European standard’.

In the green wave, Fanqun engraves environmental protection into its genes: sludge resourcing technology helps Southeast Asian cities to reduce pollution, low-carbon hot air furnace reduces emissions by 30%, and agricultural product drying programme drives a billion rural economy. With pressure vessel manufacturing licence and ISO double certification in hand, and a steady AAA grade credit enterprise for 13 consecutive years, Fanqun uses the temperature of drying technology to balance industrial development and ecological harmony.

From the small town of Changzhou to the world stage, Fanqun Drying always takes ‘drying the dignity of Chinese manufacturing’ as its mission, and makes every grain of material sublimation, all of which is the note of the times. |