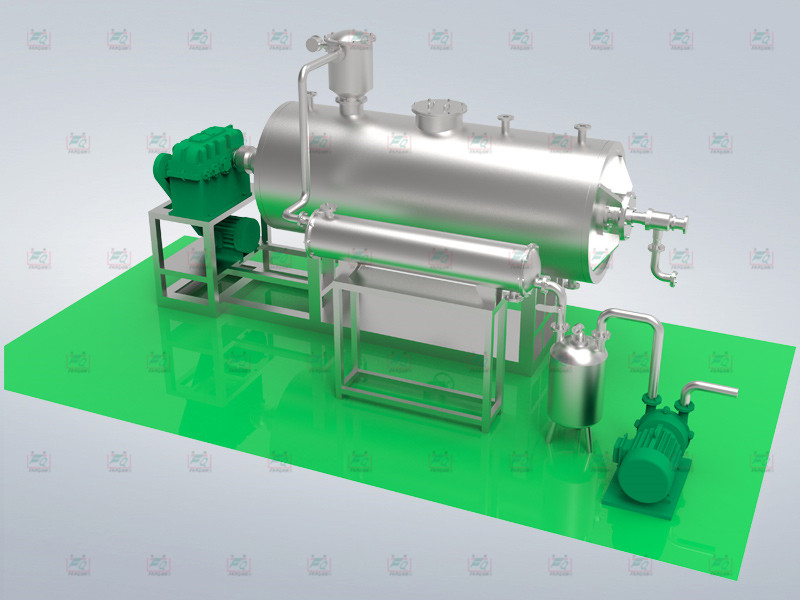

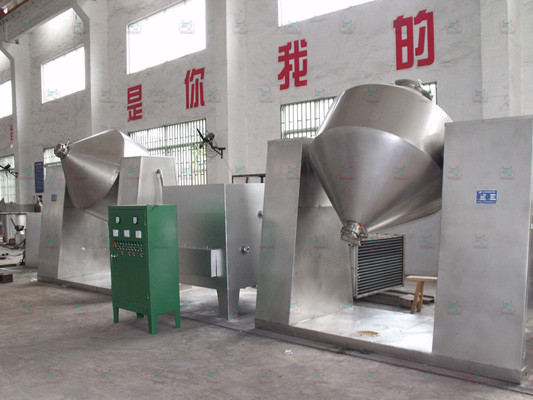

PZG Harrow Dryer, Rake Dryer, Rake Drying Machine

Experience superior vacuum drying performance with our PZG Harrow Dryer, Rake Dryer, and Rake Drying Machine. This advanced industrial harrow drying equipment features gentle mixing technology and precise temperature control, delivering exceptional drying efficiency for pharmaceutical, chemical, food, and fine chemical industries with vacuum operation and uniform heat distribution.

Working Principle of PZG Harrow Rake Dryer

Understand the advanced vacuum drying technology of our PZG Industrial Harrow Drying Equipment, ensuring optimal moisture removal and gentle material handling for heat-sensitive products.

Advanced Technical Features of PZG Industrial Harrow Dryer

Delivering superior performance through innovative vacuum technology, gentle mixing systems, and precise temperature control for efficient harrow drying operations.

Advanced Vacuum Drying System

Features sophisticated vacuum technology for low-temperature drying operations. The harrow dryer enables gentle processing of heat-sensitive materials while maintaining product integrity and reducing energy consumption through efficient moisture removal.

Gentle Harrow Rake Mixing

Incorporates specially designed harrow rakes for gentle material mixing and heat transfer enhancement. The rake drying machine ensures uniform drying while preventing material degradation and maintaining product quality.

Uniform Heat Distribution

Equipped with advanced heating systems providing uniform temperature distribution throughout the drying chamber. The rake dryer equipment ensures consistent product quality and optimal drying efficiency across all material zones.

Precise Temperature Control

Features advanced temperature control systems with precise monitoring and adjustment capabilities. The industrial harrow drying equipment maintains optimal drying conditions while protecting heat-sensitive materials from thermal damage.

Automated Operation & Control

Incorporates intelligent automation systems for optimal process control and monitoring. The harrow drying system provides consistent performance with minimal operator intervention and enhanced safety features.

Versatile PZG Harrow Rake Dryer Applications

From pharmaceutical formulations to fine chemicals, our PZG industrial harrow drying equipment delivers exceptional results across diverse heat-sensitive material applications.

Pharmaceutical Industry

Ideal for pharmaceutical powder drying, API processing, and drug intermediate manufacturing. Our pharmaceutical harrow dryer ensures gentle processing while maintaining product potency and meeting stringent quality standards.

Fine Chemical Processing

Perfect for fine chemical drying, specialty chemical processing, and catalyst preparation. The chemical harrow dryer provides precise control over drying conditions for high-value chemical products.

Food & Nutraceuticals

Excellent for food ingredient drying, nutraceutical processing, and heat-sensitive food product manufacturing. The food harrow drying equipment preserves nutritional value and functional properties.

Biotechnology & Life Sciences

Superior for biotechnology product drying, enzyme processing, and biological material preparation. The biotechnology harrow dryer maintains biological activity while achieving optimal moisture content.

Exceptional Value from PZG Industrial Harrow Dryer

Maximize product quality, processing efficiency, and operational flexibility with our advanced harrow drying technology.

Superior Product Quality

The PZG harrow dryer preserves product integrity through gentle vacuum drying and controlled temperature conditions. This industrial harrow drying equipment ensures consistent quality while maintaining the properties of heat-sensitive materials.

Enhanced Energy Efficiency

Vacuum operation reduces energy consumption by enabling low-temperature drying processes. The rake drying machine optimizes heat transfer efficiency while minimizing operational costs and environmental impact.

Gentle Material Handling

Specialized harrow rake design provides gentle mixing without material degradation. The rake dryer equipment ensures uniform processing while protecting delicate materials from mechanical damage.

Versatile Processing Capabilities

Accommodates various material types and moisture contents with adjustable operating parameters. The harrow drying system adapts to different processing requirements and product specifications.

Success Stories: PZG Harrow Rake Dryer in Action

Partnering with leading companies to achieve excellence in vacuum drying with our advanced industrial harrow drying solutions.

Project Challenge:

The client needed a pharmaceutical harrow dryer for heat-sensitive API processing that could achieve precise moisture control while maintaining product potency and meeting regulatory requirements.

Project Results:

• Maintained 99.5% API potency

• Achieved ±0.05% moisture accuracy

• Reduced processing time by 40%

• Met all regulatory compliance standards

Project Challenge:

The facility required a chemical harrow dryer for processing high-value specialty chemicals while preventing thermal degradation and maintaining product purity for demanding applications.

Project Results:

• Eliminated thermal degradation

• Maintained 99.8% product purity

• Improved yield by 25%

• Enhanced product stability significantly

Project Challenge:

The company needed a food harrow drying equipment for processing heat-sensitive nutraceutical ingredients while preserving bioactivity and nutritional value for health supplement applications.

Project Results:

• Preserved 95% bioactivity

• Maintained nutritional integrity

• Improved product flowability by 35%

• Enhanced shelf stability significantly

Comprehensive Service Support for PZG Industrial Harrow Dryer

From consultation to maintenance, ensuring optimal performance throughout your harrow drying equipment lifecycle.

Harrow Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial harrow dryer design services tailored to your specific material properties and vacuum drying requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper harrow dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the rake drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your rake drying machine. 24/7 technical support keeps harrow drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve harrow drying system efficiency. Regular performance assessments ensure sustained optimal operation and compliance.