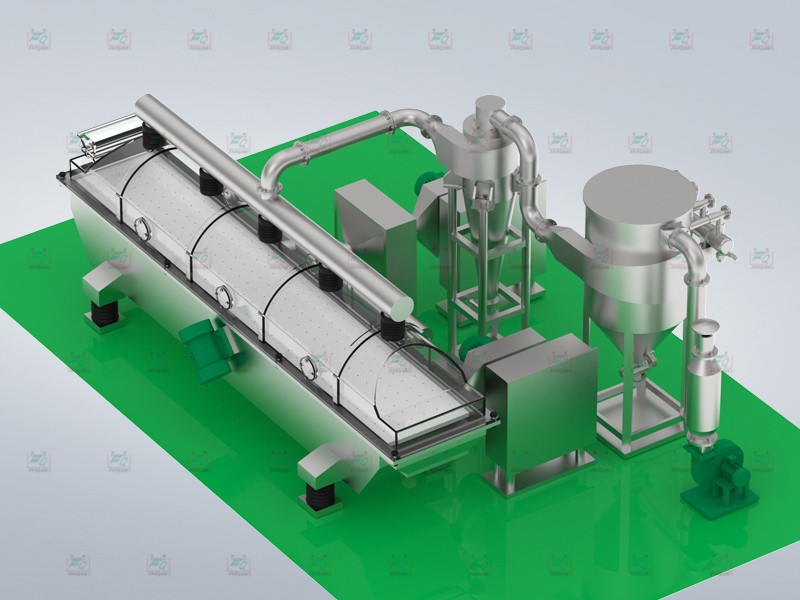

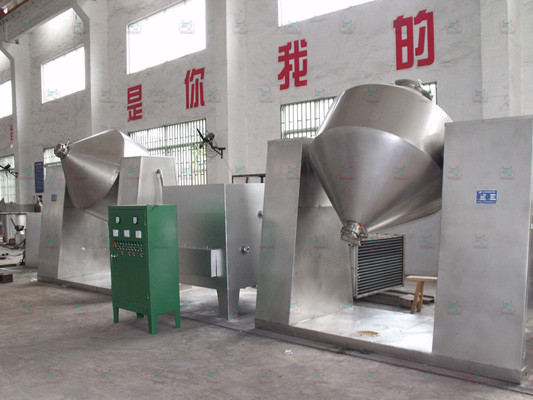

ZLG Series Vibrating Fluid Bed Dryer

Experience highly efficient and uniform drying with our ZLG Series Vibrating Fluid Bed Dryer. Designed for granular and powdered materials, it ensures optimal product quality, energy efficiency, and versatile application across various industries.

Working Principle of ZLG Series Vibrating Fluid Bed Dryer

Discover the innovative technology behind our ZLG Series Vibrating Fluid Bed Dryer, ensuring optimal drying performance and product quality.

Exceptional Value for Your Production Operations

Maximize efficiency, quality, and profitability with our advanced vibrating fluid bed drying technology.

Superior Product Quality

Achieves highly uniform drying and cooling, preventing agglomeration and ensuring consistent particle size distribution. Gentle vibration minimizes material damage, preserving product integrity and quality.

Enhanced Production Efficiency

Continuous operation with high throughput capacity significantly increases production efficiency. The combination of fluidization and vibration ensures rapid and thorough drying, reducing processing time.

Cost-Effective Operation

High thermal efficiency and optimized energy consumption lead to significant reductions in operating costs. Low maintenance requirements and durable construction ensure long-term reliability and cost savings.

Flexible & Adaptable

Adjustable parameters allow for flexible adaptation to various materials and processing requirements. Can be used for drying, cooling, or humidifying, providing a versatile solution for diverse industrial needs.

Success Stories: ZLG Vibrating Fluid Bed Dryer in Action

Partnering with leading companies across industries to achieve excellence in granular and powder drying.

Project Challenge:

The client needed to dry pharmaceutical granules uniformly while maintaining particle integrity and achieving precise moisture content for tablet compression.

Project Results:

• Moisture content achieved ±0.1% precision

• Granule integrity maintained with minimal breakage

• Drying time reduced by 60% compared to static drying

• Production capacity increased by 200%

Project Challenge:

The client required efficient drying of monosodium glutamate (MSG) crystals, ensuring uniform moisture removal and preventing caking while preserving crystal structure.

Project Results:

• Uniform moisture content achieved, preventing caking

• Crystal integrity maintained, enhancing product appearance

• Energy consumption reduced by 30%

• Production throughput increased by 150%

Project Challenge:

The client needed to dry borax powder with high initial moisture content, requiring a robust and efficient drying solution that could handle large volumes continuously.

Project Results:

• Achieved target moisture content consistently

• Continuous operation for high volume production

• Reduced drying time by 50%

• Enhanced overall process stability

Comprehensive Service Support for Your ZLG Vibrating Fluid Bed Dryer

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Process Design

Our expert engineers provide comprehensive technical consultation and process design services tailored to your specific material properties and drying requirements, ensuring optimal performance and efficiency.

Professional Installation & Commissioning

Experienced installation team ensures proper equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity and safety from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your production running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing production needs. Regular performance assessments ensure sustained optimal operation.