HG Series Rotary Drum Dryer Equipment

Experience advanced rotary drum drying technology with our HG Series Single Drum and Double Drum Dryer Equipment. Our industrial rotary drum dryer delivers exceptional performance for chemical, mineral, agricultural, and environmental applications with high capacity and superior energy efficiency.

Working Principle of HG Series Rotary Drum Dryer Equipment

Discover the innovative rotary drum technology behind our HG Series Dryer, ensuring optimal drying performance for industrial applications with both single drum and double drum configurations.

Advanced Technical Features of HG Rotary Drum Dryer Equipment

Delivering superior performance through innovative rotary drum technology and precision engineering for industrial drying applications

Single Drum & Double Drum Configurations

Our HG Series rotary drum dryer offers both single drum and double drum configurations to meet diverse industrial drying requirements. The double drum dryer provides enhanced heat transfer efficiency and increased capacity for high-volume applications.

High-Capacity Continuous Operation

Designed for continuous 24/7 operation with exceptional throughput capacity. The rotary drum dryer equipment handles large volumes of material efficiently, ensuring consistent production flow and optimal industrial drying performance.

Advanced Heat Transfer System

Features optimized lifting flights and heat transfer design for maximum thermal efficiency. The rotary drum configuration ensures uniform heat distribution and efficient moisture removal across all material particles.

Robust Construction & Durability

Built with heavy-duty materials and reinforced drum structure to withstand harsh industrial conditions. The rotary drum dryer equipment features wear-resistant linings and high-temperature resistant components for extended service life.

Efficient Dust Collection System

Integrated dust collection and emission control system ensures environmental compliance and product recovery. The rotary drum dryer includes cyclones, baghouse filters, and scrubbing systems for clean operation.

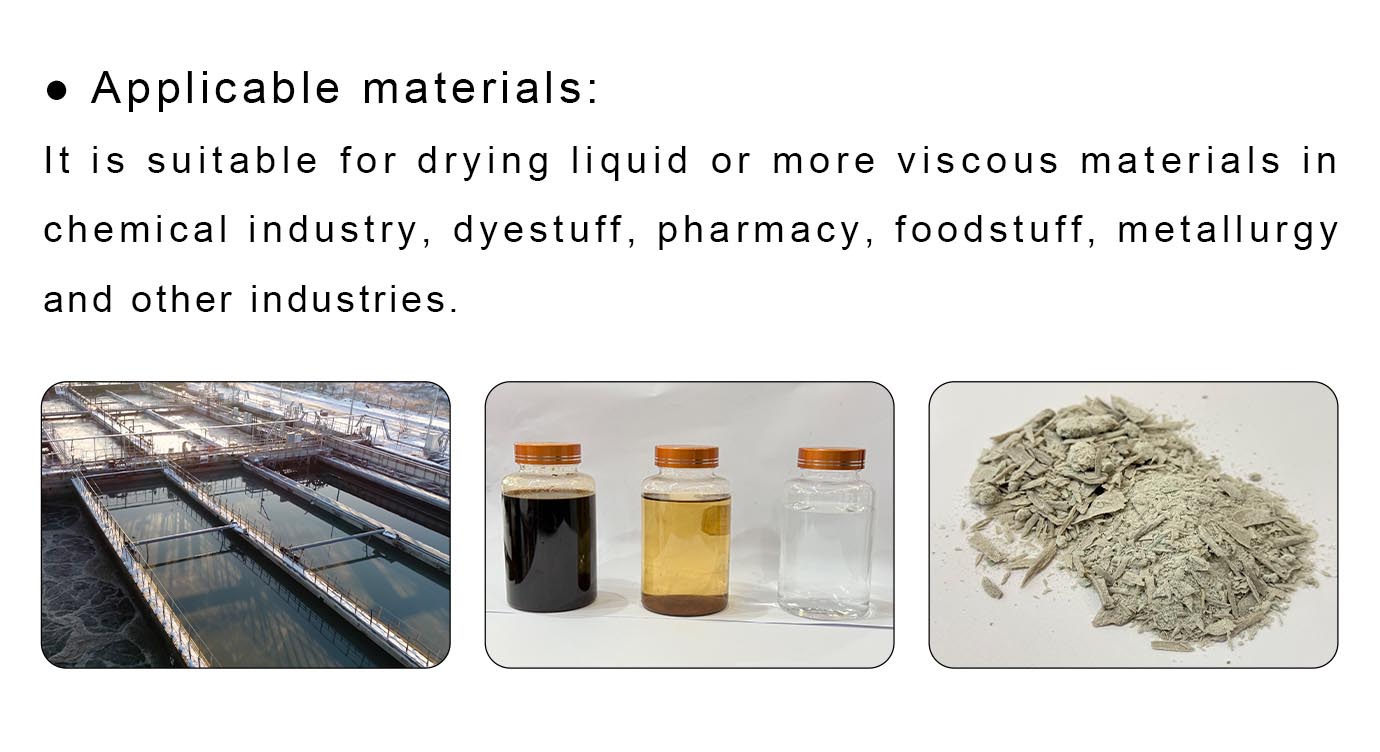

Versatile Rotary Drum Dryer Applications Across Industries

From chemical processing to environmental treatment, our HG Series rotary drum dryer equipment delivers exceptional results for diverse industrial drying applications.

Chemical Industry Drying

Ideal rotary drum dryer for chemical salts, fertilizers, catalysts, and specialty chemicals. Our drum dryer equipment handles corrosive materials and high-temperature applications with superior performance and reliability.

Mineral Processing

Perfect rotary drum dryer for sand, clay, limestone, gypsum, and industrial minerals. The drum dryer provides efficient moisture removal and particle size control for mineral processing operations.

Agricultural Products

Excellent rotary drum dryer for grain, biomass, wood chips, and agricultural waste. Our drum dryer equipment preserves product quality while achieving optimal moisture content for storage and processing.

Environmental Treatment

Superior rotary drum dryer for sludge, biosolids, and waste materials. The drum dryer equipment reduces waste volume significantly while creating opportunities for resource recovery and beneficial reuse.

Exceptional Value from HG Rotary Drum Dryer Equipment

Maximize efficiency, quality, and profitability with our advanced rotary drum drying technology and industrial drum dryer solutions.

High Production Capacity

Our rotary drum dryer equipment delivers exceptional throughput capacity with continuous operation capability. The drum dryer design ensures maximum productivity and efficient material processing for industrial applications.

Energy Efficiency & Cost Savings

Advanced heat recovery systems and optimized thermal design reduce energy consumption significantly. The rotary drum dryer provides excellent fuel efficiency and lower operating costs compared to conventional drying methods.

Reliable & Low Maintenance

Robust construction and proven rotary drum dryer technology ensure reliable operation with minimal maintenance requirements. The drum dryer equipment features accessible components and simplified maintenance procedures.

Flexible & Adaptable

Customizable rotary drum dryer configurations accommodate various materials and processing requirements. The drum dryer equipment offers adjustable parameters for optimal performance across different applications.

Success Stories: HG Rotary Drum Dryer Equipment in Action

Partnering with leading companies to achieve excellence in industrial drying with our rotary drum dryer solutions.

Project Challenge:

The client needed a high-capacity rotary drum dryer for fertilizer production, requiring efficient moisture removal while maintaining product quality and meeting environmental regulations.

Project Results:

• Achieved 50 tons/hour drying capacity

• Reduced moisture content from 15% to 2%

• Improved energy efficiency by 30%

• Met all environmental emission standards

Project Challenge:

The facility required a robust rotary drum dryer for industrial sand processing, handling abrasive materials while maintaining consistent product quality and particle size distribution.

Project Results:

• Processed 80 tons/hour of sand

• Achieved uniform moisture content below 1%

• Extended equipment life by 40%

• Reduced maintenance costs by 25%

Project Challenge:

The plant needed an efficient rotary drum dryer for biomass fuel preparation, requiring precise moisture control while preserving wood fiber integrity for optimal combustion characteristics.

Project Results:

• Achieved target moisture content of 10%

• Maintained wood fiber integrity

• Increased fuel heating value by 35%

• Generated $300,000 annual energy savings

Comprehensive Service Support for HG Rotary Drum Dryer Equipment

From consultation to maintenance, ensuring optimal performance throughout your rotary drum dryer equipment lifecycle.

Rotary Drum Dryer Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom rotary drum dryer design services tailored to your specific material properties and industrial drying requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper rotary drum dryer equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your rotary drum dryer. 24/7 technical support keeps your drum dryer operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve rotary drum dryer efficiency. Regular performance assessments ensure sustained optimal operation and compliance.