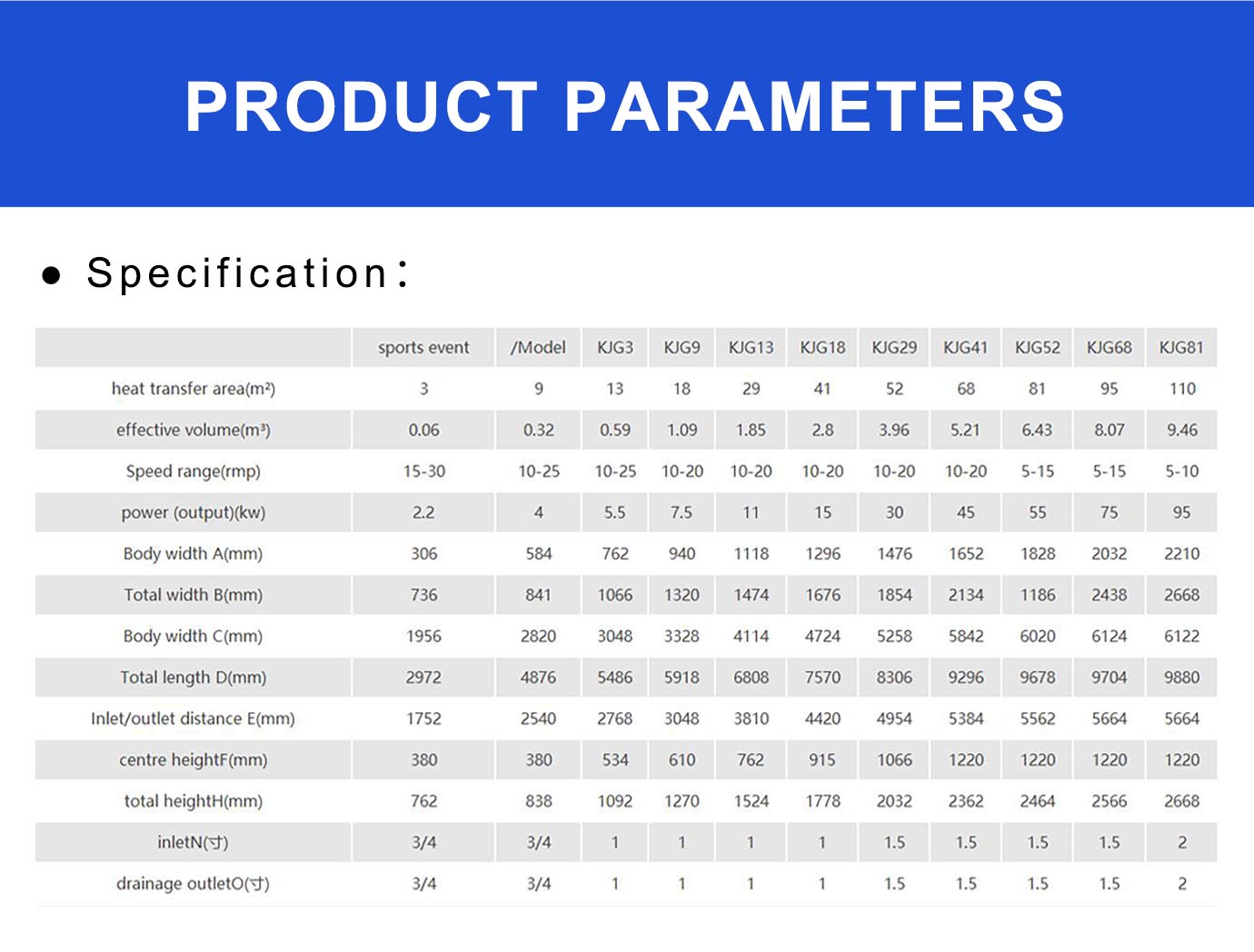

KJG Series Sludge Drying Machine

Experience efficient and reliable sludge treatment with our advanced KJG Series Hollow Paddle Dryer. Designed for municipal, industrial, and biosolids drying applications, it delivers superior performance with high thermal efficiency and low energy consumption.

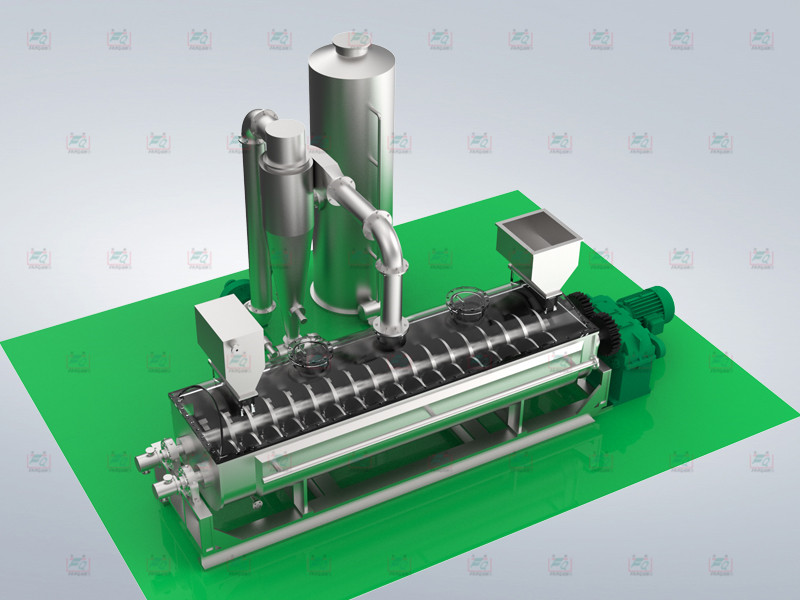

Working Principle of KJG Series Sludge Drying Machine

Discover the innovative hollow paddle technology behind our KJG Series Sludge Dryer, ensuring optimal drying performance and energy efficiency.

Advanced Technical Features of KJG Sludge Drying Machine

Delivering superior performance through innovative hollow paddle technology and precision engineering

Hollow Paddle Heat Transfer Technology

Features specially designed hollow paddles with large heat transfer surface area, ensuring efficient indirect heating. The wedge-shaped paddles provide excellent self-cleaning properties and prevent material buildup, maintaining consistent heat transfer performance.

Low Temperature Drying Process

Operates at relatively low temperatures (100-250°C), preserving sludge characteristics and preventing thermal decomposition. This gentle drying process is ideal for heat-sensitive materials and reduces energy consumption significantly.

Continuous Operation Capability

Designed for continuous 24/7 operation with high reliability and minimal maintenance requirements. The robust construction and quality components ensure stable performance even under demanding industrial conditions.

Compact Design & Space Efficiency

Compact footprint design maximizes drying capacity while minimizing space requirements. The enclosed system reduces environmental impact and eliminates odor emissions, making it suitable for urban installations.

Advanced Control System

Equipped with intelligent PLC control system for precise temperature, residence time, and moisture content control. Real-time monitoring and automatic adjustment ensure optimal drying performance and product quality.

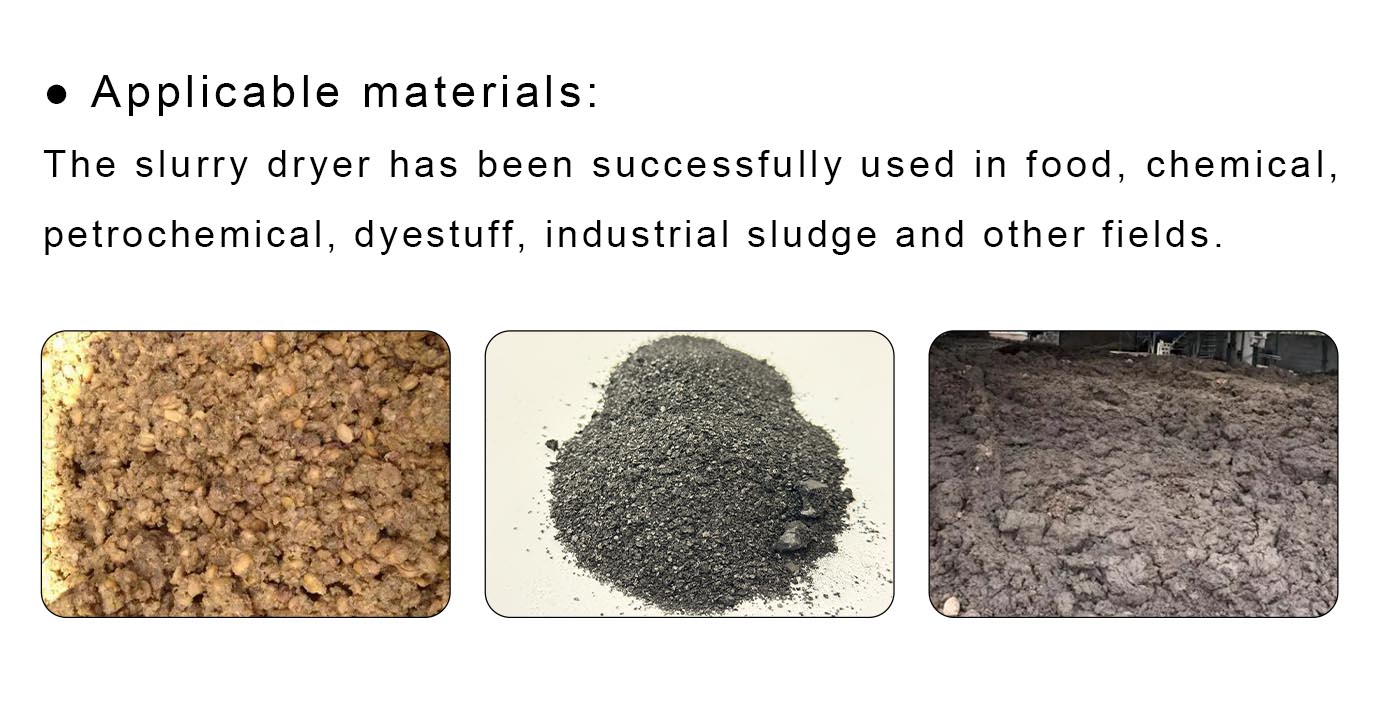

Versatile Applications Across Industries

From municipal wastewater treatment to industrial sludge processing, our KJG Series delivers exceptional results across diverse applications.

Municipal Wastewater Treatment

Ideal for drying municipal sewage sludge, biosolids, and digested sludge from wastewater treatment plants. Reduces sludge volume by 80-90%, significantly lowering disposal costs and transportation requirements.

Industrial Sludge Processing

Perfect for treating industrial sludge from chemical, pharmaceutical, food processing, and textile industries. Handles various types of industrial waste sludge with high efficiency and reliability.

Agricultural & Organic Waste

Suitable for drying animal manure, agricultural waste, and organic sludge. Produces valuable dried organic fertilizer while reducing environmental impact and improving waste management efficiency.

Paper & Pulp Industry

Excellent for drying paper mill sludge, pulp waste, and fiber sludge. Recovers valuable fiber content while reducing waste volume and creating opportunities for resource recovery and reuse.

Exceptional Value for Your Sludge Treatment Operations

Maximize efficiency, reduce costs, and improve environmental compliance with our advanced sludge drying technology.

Significant Cost Reduction

Reduces sludge volume by 80-90%, dramatically lowering transportation and disposal costs. High thermal efficiency and low energy consumption result in substantial operational savings and improved ROI.

Enhanced Environmental Compliance

Enclosed system eliminates odor emissions and reduces environmental impact. Meets strict environmental regulations and improves community relations through responsible waste management practices.

Resource Recovery Opportunities

Dried sludge can be used as fuel, fertilizer, or construction material, creating additional revenue streams. Heat recovery systems further improve energy efficiency and reduce operating costs.

Operational Excellence

Continuous operation capability with minimal maintenance requirements ensures high availability and productivity. Automated control systems reduce labor costs and improve process consistency.

Success Stories: KJG Sludge Drying Machine in Action

Partnering with leading organizations to achieve excellence in sludge treatment and environmental management.

Project Challenge:

The plant needed to reduce sludge disposal costs and meet new environmental regulations while handling 50 tons/day of sewage sludge with 80% moisture content.

Project Results:

• Sludge volume reduced by 85%, saving $500,000 annually in disposal costs

• Moisture content reduced from 80% to 10%

• Energy consumption 40% lower than alternative technologies

• Zero odor emissions, improving community relations

Project Challenge:

The client required efficient treatment of chemical process sludge with varying compositions, demanding a robust and flexible drying solution for continuous operation.

Project Results:

• Successfully processed 15 different sludge types

• Achieved 95% moisture reduction consistently

• Continuous operation for 8,760 hours annually

• Recovered valuable chemicals worth $200,000/year

Project Challenge:

The facility needed to convert animal manure and organic waste into valuable fertilizer while managing large volumes and meeting environmental standards.

Project Results:

• Produced 2,000 tons/year of high-quality organic fertilizer

• Reduced waste volume by 90%

• Generated $300,000 annual revenue from fertilizer sales

• Eliminated groundwater contamination risks

Comprehensive Service Support for Your KJG Sludge Drying Machine

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Process Design

Our expert engineers provide comprehensive technical consultation and process design services tailored to your specific sludge characteristics and treatment requirements, ensuring optimal performance and efficiency.

Professional Installation & Commissioning

Experienced installation team ensures proper equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity and safety from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your sludge treatment operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing treatment needs. Regular performance assessments ensure sustained optimal operation and compliance.