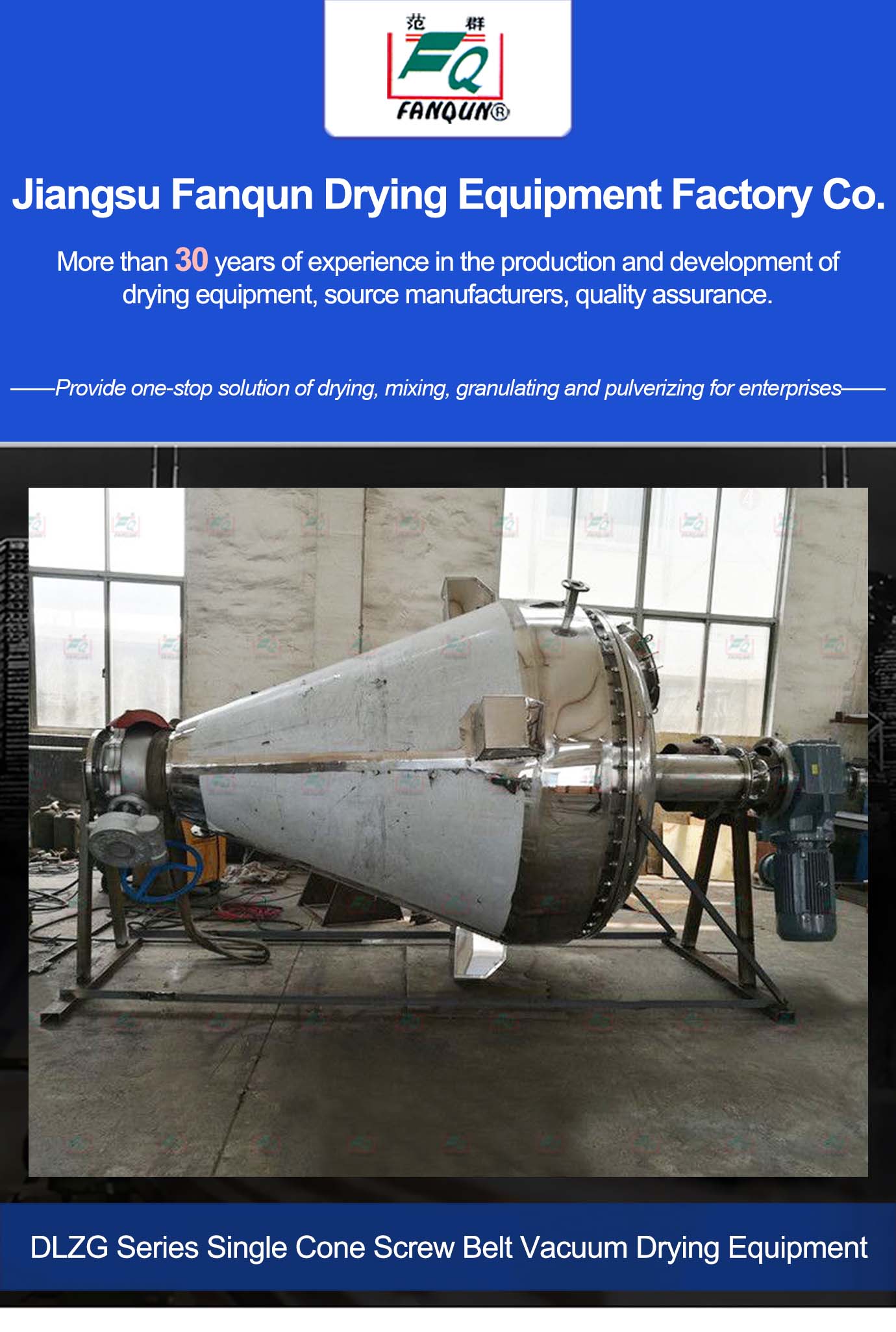

DLZG Series Single Cone Screw Belt Vacuum Drying Equipment

Experience advanced vacuum drying technology with our DLZG Series Single Cone Screw Belt Vacuum Dryer. Designed for heat-sensitive materials, it ensures gentle processing, high efficiency, and superior product quality across pharmaceutical, chemical, and fine chemical industries.

Working Principle of DLZG Series Vacuum Drying Equipment

Discover the innovative single cone screw belt technology behind our DLZG Series Vacuum Dryer, ensuring optimal drying performance for heat-sensitive materials.

Advanced Technical Features of DLZG Vacuum Drying Equipment

Delivering superior performance through innovative vacuum technology and precision engineering

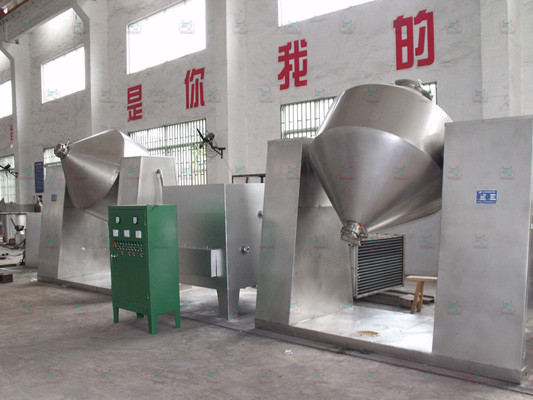

Single Cone Design with Screw Belt Agitator

Features a unique single cone vessel with specially designed screw belt agitator that provides gentle mixing action. This design ensures uniform heat distribution, prevents material sticking, and maintains product integrity throughout the drying process.

Advanced Vacuum System

Equipped with high-performance vacuum pump system capable of achieving deep vacuum levels (up to 0.1 mbar). This enables low-temperature drying, preserving heat-sensitive compounds and preventing thermal degradation.

Precise Temperature Control

Utilizes jacket heating with thermal oil or steam circulation for precise temperature control. Multiple temperature zones and advanced PID control ensure optimal drying conditions and consistent product quality.

Efficient Solvent Recovery

Integrated condenser system enables efficient recovery of solvents and valuable compounds. This feature reduces operating costs, minimizes environmental impact, and allows for solvent recycling in pharmaceutical applications.

GMP Compliant Construction

Constructed with high-quality stainless steel (316L) with mirror-polished surfaces meeting GMP standards. Features crevice-free design, easy cleaning validation, and full documentation for pharmaceutical applications.

Versatile Applications Across Industries

From pharmaceutical APIs to fine chemicals, our DLZG Series delivers exceptional results for heat-sensitive material processing.

Pharmaceutical Industry

Ideal for drying APIs, intermediates, antibiotics, and steroids. Gentle vacuum drying preserves molecular structure and biological activity while meeting strict pharmaceutical quality standards and regulatory requirements.

Fine Chemical Processing

Perfect for drying specialty chemicals, catalysts, pigments, and dyes. Low-temperature processing prevents decomposition and maintains chemical purity, ensuring high-quality end products.

Food & Nutraceutical

Suitable for drying heat-sensitive food ingredients, vitamins, probiotics, and nutraceutical compounds. Preserves nutritional value, flavor, and bioactivity while achieving desired moisture content.

Biotechnology & Research

Excellent for drying biological materials, enzymes, proteins, and research compounds. Gentle processing conditions maintain biological activity and molecular integrity for critical applications.

Exceptional Value for Your Processing Operations

Maximize product quality, efficiency, and profitability with our advanced vacuum drying technology.

Superior Product Quality

Low-temperature vacuum drying preserves heat-sensitive compounds, maintains molecular structure, and prevents thermal degradation. Gentle processing ensures maximum product integrity and bioactivity retention.

Enhanced Process Efficiency

Vacuum conditions significantly reduce drying time and energy consumption. Efficient heat transfer and uniform mixing ensure rapid moisture removal while maintaining gentle processing conditions.

Solvent Recovery & Cost Savings

Integrated solvent recovery system captures and recycles valuable solvents, reducing raw material costs and environmental impact. High recovery efficiency provides significant operational savings.

Regulatory Compliance

GMP-compliant design meets pharmaceutical industry standards and regulatory requirements. Complete documentation, validation support, and quality assurance ensure smooth regulatory approval processes.

Success Stories: DLZG Vacuum Drying Equipment in Action

Partnering with leading companies to achieve excellence in heat-sensitive material processing.

Project Challenge:

The client needed to dry heat-sensitive antibiotic compounds while maintaining biological activity and meeting strict pharmaceutical quality standards for sterile production.

Project Results:

• Maintained 99.5% biological activity retention

• Achieved moisture content below 0.5%

• Reduced drying time by 70% compared to tray drying

• 95% solvent recovery efficiency achieved

Project Challenge:

The client required gentle drying of expensive specialty catalysts without thermal decomposition, while recovering valuable organic solvents for reuse in production.

Project Results:

• Zero thermal decomposition achieved

• Catalyst activity maintained at 100%

• 98% solvent recovery rate

• Annual savings of $150,000 in solvent costs

Project Challenge:

The facility needed to dry live probiotic cultures while maintaining viability and potency, requiring extremely gentle processing conditions and precise moisture control.

Project Results:

• Maintained 90% probiotic viability

• Achieved target moisture content of 3%

• Extended shelf life by 200%

• Improved product stability and quality

Comprehensive Service Support for Your DLZG Vacuum Drying Equipment

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Process Design

Our expert engineers provide comprehensive technical consultation and process design services tailored to your specific material properties and drying requirements, ensuring optimal vacuum drying performance.

Professional Installation & Validation

Experienced installation team ensures proper equipment setup and commissioning. Complete validation documentation and operator training programs enable your team to achieve maximum productivity from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your vacuum drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing production needs. Regular performance assessments ensure sustained optimal operation and compliance.