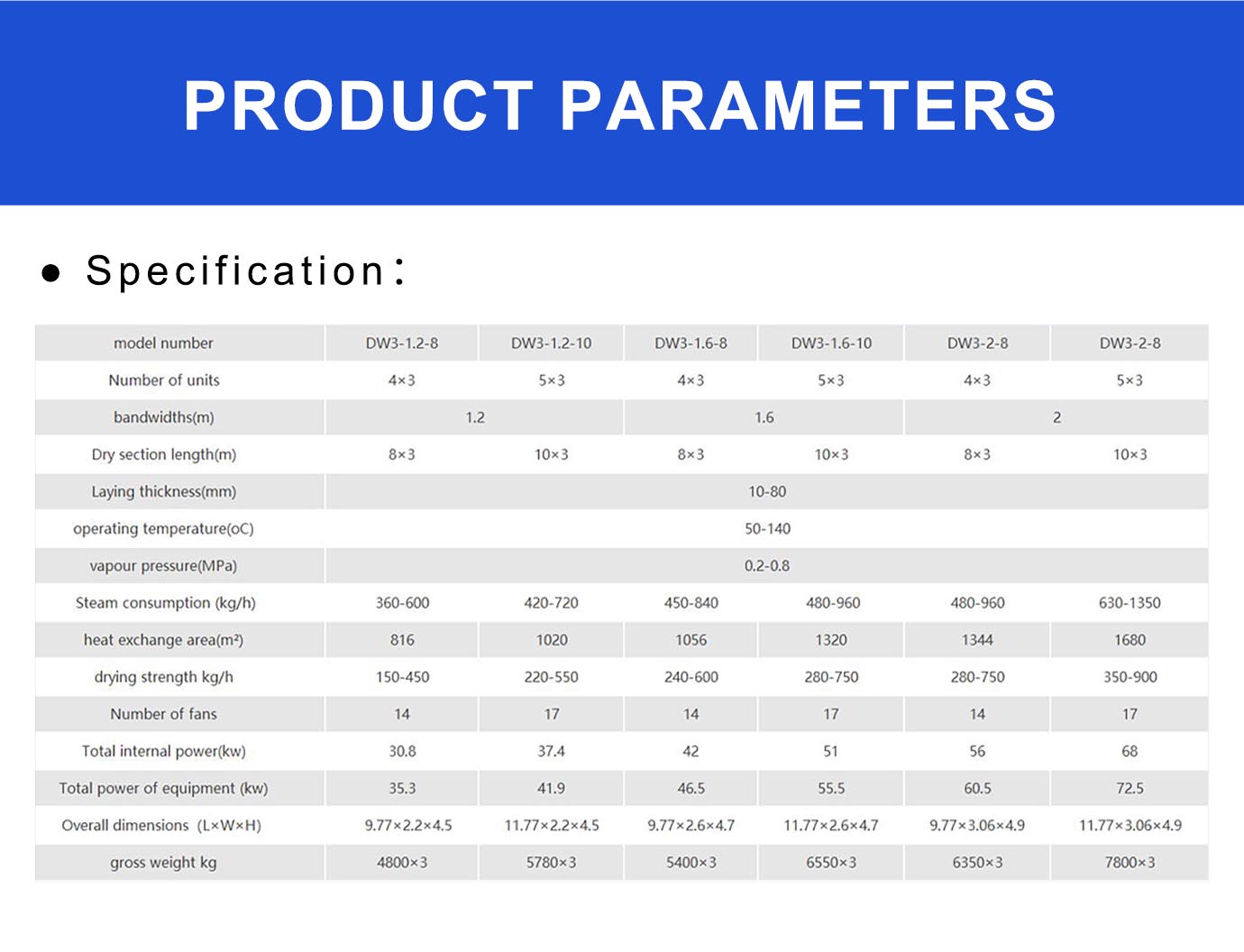

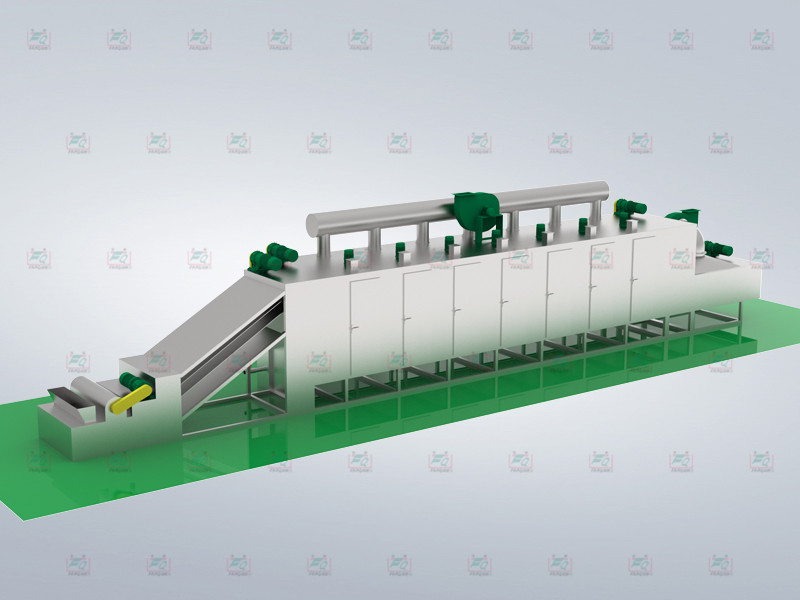

DW Series Multilayer Belt Dryer, Belt Drying Machine

Experience superior continuous drying performance with our DW Series Multilayer Belt Dryer, Belt Drying Machine. This advanced industrial belt dryer features multilayer technology and energy-efficient operation, delivering exceptional moisture removal for food, chemical, pharmaceutical, and agricultural industries with precise temperature control and uniform drying results.

Working Principle of DW Multilayer Belt Dryer

Understand the advanced continuous drying technology of our DW Series Industrial Belt Drying Machine, ensuring optimal moisture removal and efficient material processing through multilayer belt systems.

Advanced Technical Features of DW Industrial Belt Dryer

Delivering superior performance through innovative multilayer design, precise temperature control, and energy-efficient operation for continuous belt drying applications.

Multilayer Belt Design

Features advanced multilayer belt configuration for maximum drying efficiency and space utilization. The belt drying machine provides multiple processing stages within a compact footprint while ensuring uniform material distribution and optimal heat transfer.

Continuous Operation Capability

Designed for 24/7 continuous operation with automated material handling and discharge systems. The industrial belt dryer ensures consistent production output while minimizing labor requirements and operational interruptions.

Precise Temperature Control

Equipped with advanced temperature control systems for each drying zone. The multilayer belt dryer maintains optimal drying conditions throughout the process, ensuring consistent product quality and preventing thermal damage.

Energy Recovery Systems

Incorporates heat recovery and energy recycling systems for maximum efficiency. The belt drying equipment reduces energy consumption through optimized air circulation and waste heat recovery technologies.

Flexible Processing Parameters

Offers adjustable belt speed, temperature zones, and airflow patterns for different materials. The continuous belt drying system adapts to various product requirements and processing specifications with ease.

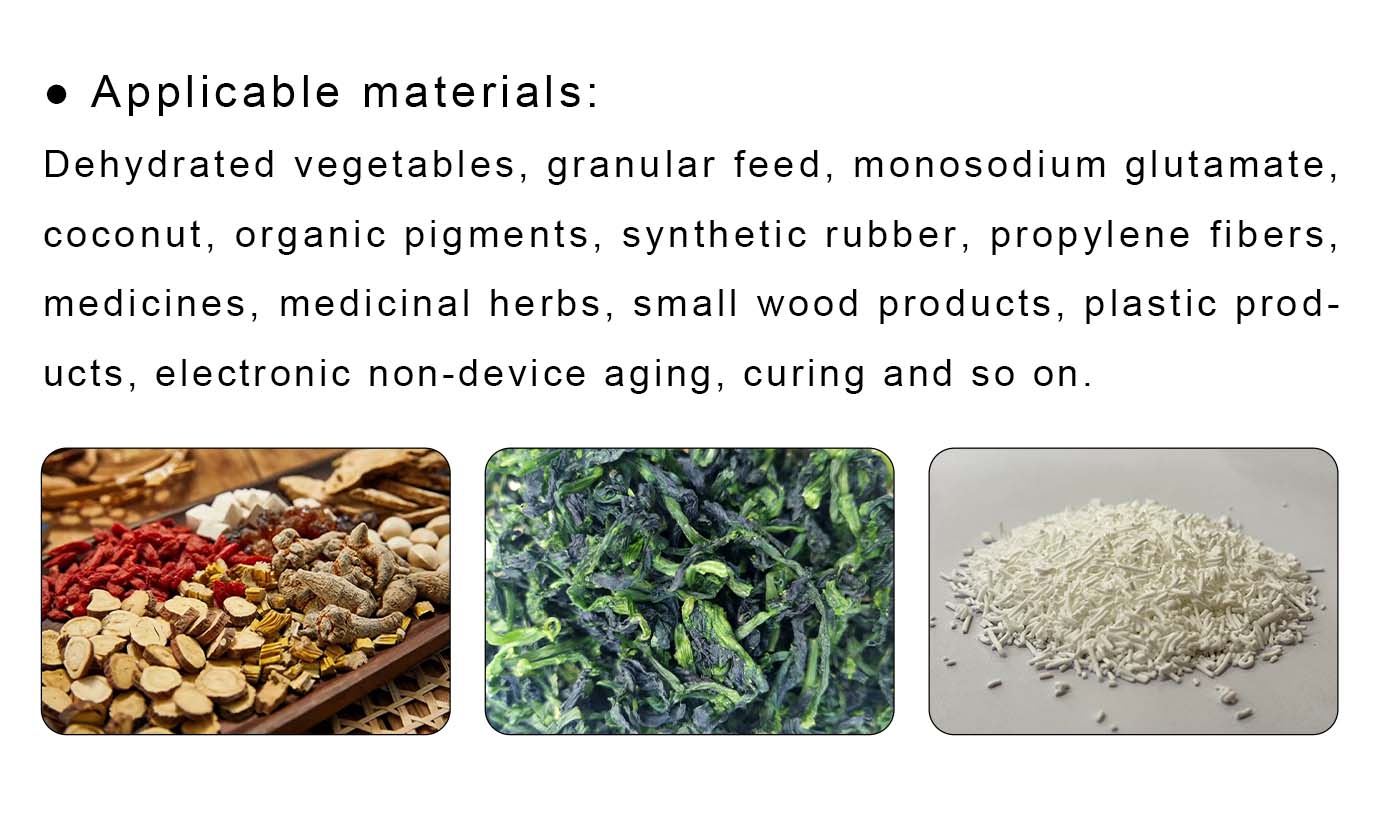

Versatile DW Multilayer Belt Dryer Applications

From food processing to pharmaceutical manufacturing, our DW Series industrial belt dryer delivers exceptional results across diverse continuous drying applications.

Food Processing Industry

Ideal for food dehydration, vegetable drying, fruit processing, and snack food production. Our food belt dryer ensures gentle processing while maintaining nutritional value and product quality.

Pharmaceutical Manufacturing

Perfect for pharmaceutical granule drying, tablet coating, and drug intermediate processing. The pharmaceutical belt drying machine maintains product integrity while meeting regulatory standards.

Chemical Processing

Excellent for chemical powder drying, catalyst processing, and specialty chemical manufacturing. The chemical belt dryer provides precise control over drying conditions for sensitive materials.

Agricultural Products

Superior for grain drying, seed processing, and agricultural waste treatment. The agricultural belt drying equipment ensures optimal moisture content for storage and processing.

Exceptional Value from DW Industrial Belt Dryer

Maximize production efficiency, energy savings, and product quality with our advanced multilayer belt drying technology.

High Production Capacity

The DW multilayer belt dryer achieves exceptional throughput through continuous operation and multilayer design. This industrial belt drying machine significantly increases production capacity while maintaining consistent product quality.

Energy Efficiency & Cost Savings

Advanced heat recovery systems and optimized airflow design minimize energy consumption. The belt drying equipment reduces operational costs through efficient thermal management and automated operation.

Consistent Product Quality

Precise temperature control and uniform airflow ensure consistent drying results. The multilayer belt drying system maintains product specifications while preventing over-drying or under-drying issues.

Flexible & Scalable Design

Modular construction allows for easy capacity expansion and process modifications. The continuous belt drying equipment adapts to changing production requirements and future growth needs.

Success Stories: DW Multilayer Belt Dryer in Action

Partnering with leading companies to achieve excellence in continuous drying with our advanced industrial belt drying solutions.

Project Challenge:

The client needed a food belt dryer for large-scale vegetable dehydration that could maintain nutritional value while achieving consistent moisture content and high production throughput.

Project Results:

• Increased production capacity by 150%

• Maintained 95% nutritional retention

• Reduced energy consumption by 30%

• Achieved consistent moisture specifications

Project Challenge:

The facility required a pharmaceutical belt drying machine for granule processing that could meet GMP standards while providing gentle drying and precise moisture control.

Project Results:

• Met all GMP compliance requirements

• Achieved ±0.2% moisture accuracy

• Improved product uniformity by 40%

• Reduced processing time by 35%

Project Challenge:

The company needed a chemical belt dryer for specialty chemical processing that could handle heat-sensitive materials while maintaining product stability and purity.

Project Results:

• Preserved product stability completely

• Maintained 99.5% product purity

• Eliminated thermal degradation

• Enhanced production efficiency by 45%

Comprehensive Service Support for DW Industrial Belt Dryer

From consultation to maintenance, ensuring optimal performance throughout your belt drying equipment lifecycle.

Belt Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial belt dryer design services tailored to your specific material properties and continuous drying requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper multilayer belt dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the belt drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your belt drying machine. 24/7 technical support keeps continuous drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve multilayer belt drying system efficiency. Regular performance assessments ensure sustained optimal operation and compliance.