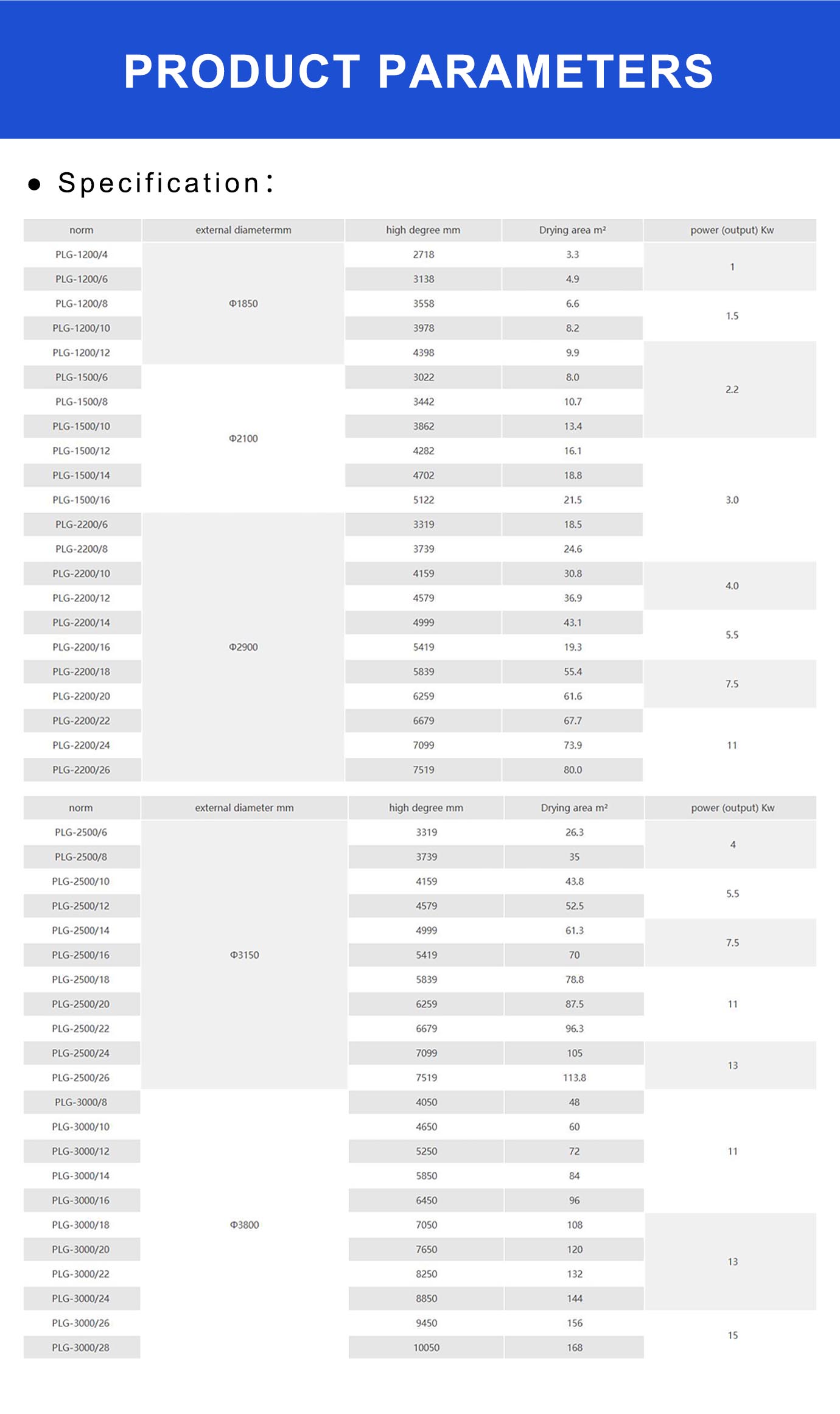

PLG Series Disc Dryer & Plate Dryer

Experience advanced continuous drying technology with our PLG Series Disc Dryer & Plate Dryer. Designed for paste, slurry, and granular materials, it ensures efficient processing, excellent heat transfer, and superior product quality across multiple industries.

Working Principle of PLG Series Disc Dryer & Plate Dryer

Discover the innovative disc and plate technology behind our PLG Series Dryer, ensuring optimal drying performance for various materials.

Advanced Technical Features of PLG Disc Dryer & Plate Dryer

Delivering superior performance through innovative disc technology and precision engineering

Multi-Disc Heat Transfer System

Features multiple heated discs with large heat transfer surface area, ensuring efficient indirect heating. The disc design provides excellent heat transfer coefficient and uniform temperature distribution throughout the drying process.

Continuous Operation Capability

Designed for continuous 24/7 operation with high throughput capacity. The continuous feeding and discharge system ensures steady production flow and consistent product quality without batch-to-batch variations.

Gentle Material Handling

Rotating discs with specially designed scrapers provide gentle material movement, preventing damage to heat-sensitive materials. Low shear processing maintains product integrity and quality characteristics.

Efficient Vapor Management

Integrated vapor collection and condensation system efficiently removes moisture and recovers solvents. This feature reduces environmental impact and enables solvent recycling for cost savings.

Precise Process Control

Advanced PLC control system with HMI interface provides precise control over temperature, residence time, and disc rotation speed. Real-time monitoring ensures optimal drying conditions and consistent product quality.

Versatile Applications Across Industries

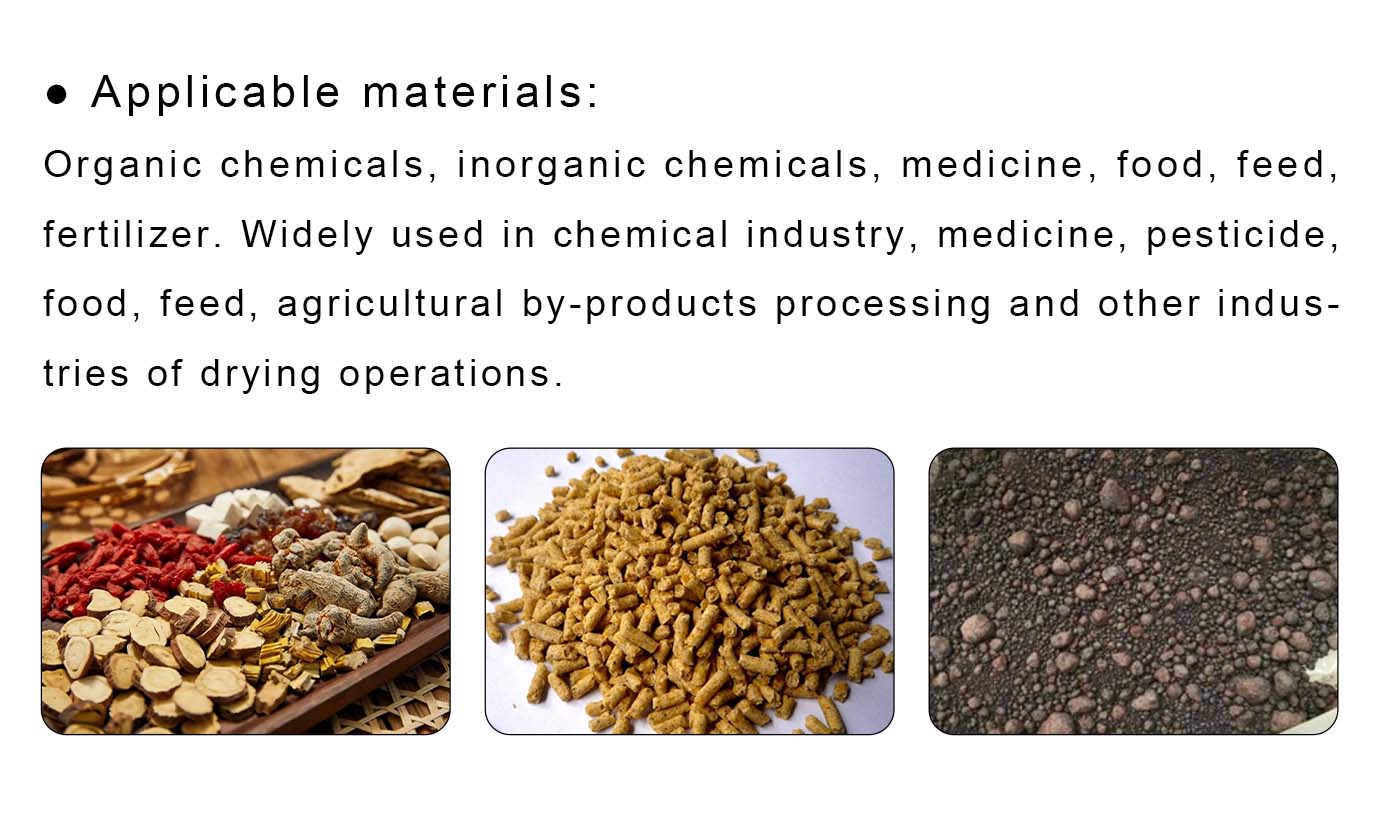

From chemical processing to environmental treatment, our PLG Series delivers exceptional results for diverse material drying applications.

Chemical Industry

Ideal for drying chemical pastes, slurries, and filter cakes. Handles various chemical products including pigments, dyes, catalysts, and specialty chemicals with high efficiency and product quality.

Pharmaceutical Processing

Perfect for drying pharmaceutical intermediates, APIs, and wet granules. Gentle processing conditions preserve active ingredients while meeting strict pharmaceutical quality standards and GMP requirements.

Food & Feed Industry

Suitable for drying food pastes, animal feed, and agricultural products. Maintains nutritional value and flavor while achieving desired moisture content for extended shelf life and storage stability.

Environmental Treatment

Excellent for drying municipal and industrial sludge, biosolids, and waste materials. Reduces waste volume significantly while creating opportunities for resource recovery and beneficial reuse.

Exceptional Value for Your Processing Operations

Maximize efficiency, quality, and profitability with our advanced disc drying technology.

Enhanced Production Efficiency

Continuous operation with high throughput capacity significantly increases production efficiency. Large heat transfer surface area and efficient material movement ensure rapid drying and consistent product quality.

Superior Product Quality

Gentle processing conditions and uniform heat distribution preserve product characteristics and prevent thermal damage. Consistent moisture content and particle size distribution ensure high-quality end products.

Cost-Effective Operation

High thermal efficiency and optimized energy consumption lead to significant reductions in operating costs. Continuous operation eliminates batch processing inefficiencies and reduces labor requirements.

Flexible & Reliable

Adaptable to various materials and processing conditions with adjustable parameters. Robust construction and reliable operation ensure minimal downtime and consistent performance over extended periods.

Success Stories: PLG Disc Dryer & Plate Dryer in Action

Partnering with leading companies to achieve excellence in continuous material drying.

Project Challenge:

The client needed to continuously dry pigment paste while maintaining color consistency and preventing agglomeration, requiring precise temperature control and gentle handling.

Project Results:

• Maintained color consistency across all batches

• Achieved moisture content below 1%

• Increased production capacity by 300%

• Reduced energy consumption by 25%

Project Challenge:

The facility required continuous drying of pharmaceutical intermediates while meeting GMP standards and maintaining API purity throughout the process.

Project Results:

• Maintained 99.9% API purity

• Achieved GMP compliance certification

• Reduced processing time by 50%

• Eliminated cross-contamination risks

Project Challenge:

The plant needed to reduce sludge volume for disposal while creating a stable, pathogen-free product suitable for beneficial reuse applications.

Project Results:

• Reduced sludge volume by 80%

• Achieved Class A biosolids standard

• Generated $400,000 annual savings in disposal costs

• Created revenue stream from biosolids sales

Comprehensive Service Support for Your PLG Disc Dryer & Plate Dryer

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Process Design

Our expert engineers provide comprehensive technical consultation and process design services tailored to your specific material properties and drying requirements, ensuring optimal disc drying performance.

Professional Installation & Commissioning

Experienced installation team ensures proper equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity and safety from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your disc drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing production needs. Regular performance assessments ensure sustained optimal operation and compliance.