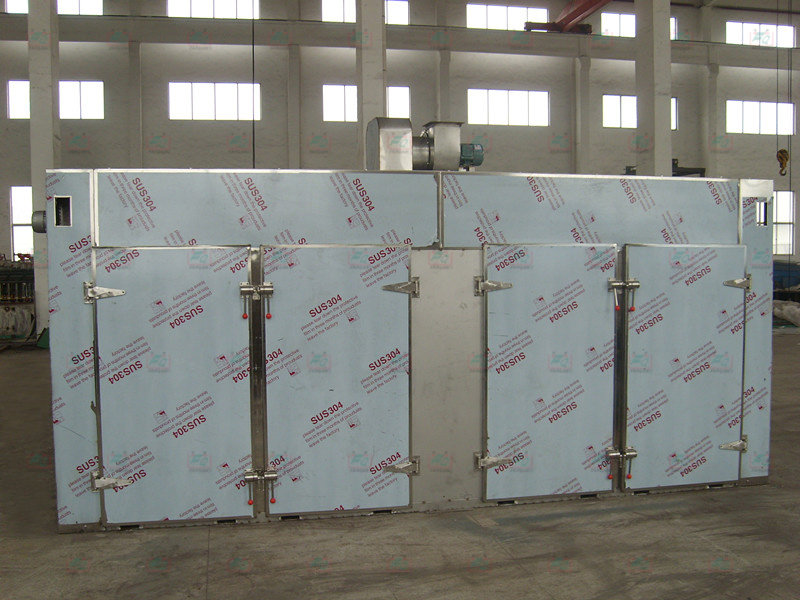

CT-C Series Hot Air Circulation Oven

Experience advanced forced air circulation drying technology with our CT-C Series Hot Air Circulation Oven. Our industrial drying oven delivers exceptional performance for pharmaceutical, food, chemical, and agricultural applications with precise temperature control and uniform heat distribution.

Working Principle of CT-C Hot Air Circulation Oven

Discover the innovative forced air circulation technology behind our CT-C Series Industrial Drying Oven, ensuring optimal drying performance for pharmaceutical and industrial applications.

Advanced Technical Features of CT-C Hot Air Circulation Oven

Delivering superior performance through innovative forced air circulation technology and precision engineering for industrial drying applications

Advanced Forced Air Circulation System

Features high-temperature resistant axial flow fans with optimized air duct design for maximum circulation efficiency. The hot air circulation oven ensures uniform temperature distribution and eliminates hot spots for consistent drying results.

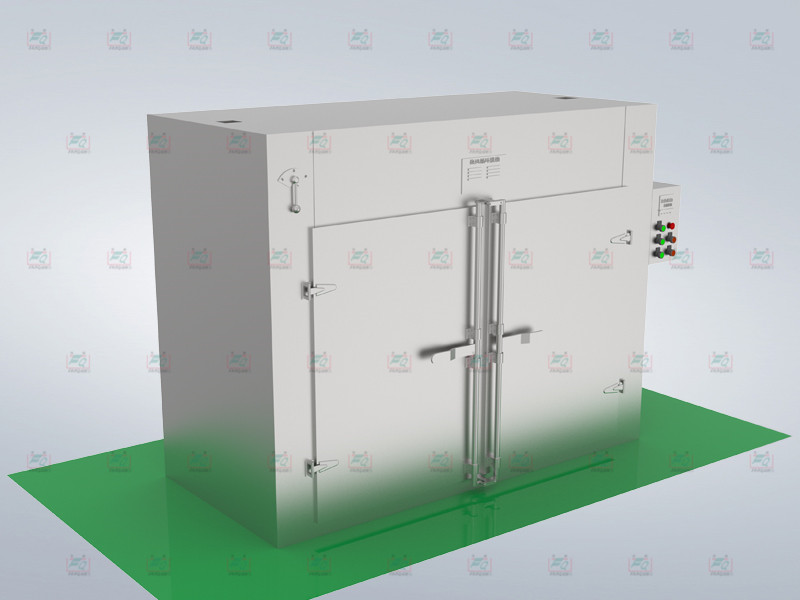

Precise Temperature Control

Equipped with advanced PID temperature control system with digital display and programmable settings. The industrial drying oven maintains temperature accuracy within ±1°C for pharmaceutical and precision applications.

Energy Efficient Design

Optimized thermal insulation and heat recovery system significantly reduce energy consumption. The hot air circulation oven achieves 35-45% thermal efficiency compared to 3-7% in traditional ovens.

GMP Compliant Construction

Constructed with pharmaceutical-grade stainless steel (304/316L) with mirror-polished surfaces. The pharmaceutical hot air oven meets GMP standards with complete validation documentation and cGMP compliance.

Flexible Tray Configuration

Accommodates various tray sizes and configurations with adjustable spacing. The industrial drying oven features removable perforated trays for easy loading, unloading, and cleaning operations.

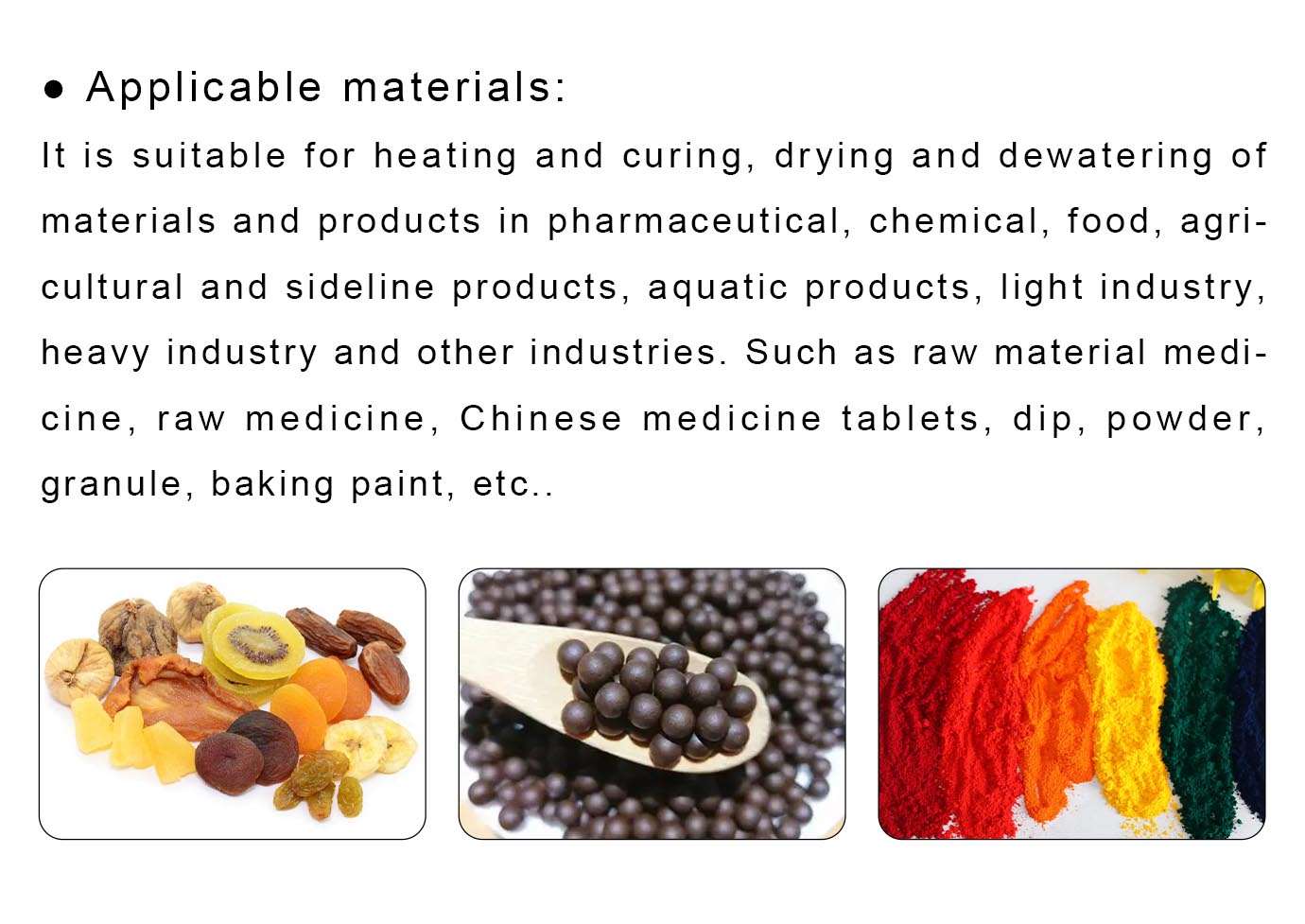

Versatile Hot Air Circulation Oven Applications

From pharmaceutical manufacturing to food processing, our CT-C Series industrial drying oven delivers exceptional results for diverse thermal processing applications.

Pharmaceutical Industry

Ideal pharmaceutical hot air oven for APIs, tablets, granules, powders, and herbal medicines. Our hot air circulation oven provides gentle drying while maintaining pharmaceutical quality and meeting GMP requirements.

Food Processing

Perfect industrial drying oven for fruits, vegetables, spices, herbs, and food ingredients. The hot air circulation oven preserves nutritional value, color, and flavor while achieving optimal moisture content.

Chemical Processing

Excellent hot air circulation oven for chemical powders, catalysts, pigments, and specialty chemicals. Our industrial drying oven handles various chemical materials with precise temperature control and contamination prevention.

Agricultural Products

Superior pharmaceutical hot air oven for seeds, grains, agricultural products, and biomass materials. The hot air circulation oven maintains product quality while achieving desired moisture levels for storage.

Exceptional Value from CT-C Hot Air Circulation Oven

Maximize efficiency, quality, and profitability with our advanced forced air circulation technology and industrial drying capabilities.

Superior Product Quality

Uniform heat distribution in the hot air circulation oven ensures consistent drying and maintains product characteristics. The industrial drying oven preserves color, texture, and active compounds for premium quality results.

Enhanced Energy Efficiency

Advanced thermal design and heat recovery systems reduce energy consumption by up to 40%. The pharmaceutical hot air oven provides excellent return on investment through reduced operating costs.

Reliable & Low Maintenance

Robust construction and proven hot air circulation technology ensure reliable operation with minimal maintenance. The industrial drying oven features accessible components and simplified maintenance procedures.

Flexible & Versatile

Adjustable temperature settings, tray configurations, and processing parameters accommodate various materials. The hot air circulation oven adapts to different production requirements and batch sizes.

Success Stories: CT-C Hot Air Circulation Oven in Action

Partnering with leading companies to achieve excellence in industrial drying with our pharmaceutical hot air oven solutions.

Project Challenge:

The client needed a GMP-compliant pharmaceutical hot air oven for API drying, requiring precise temperature control while maintaining product stability and meeting regulatory requirements.

Project Results:

• Achieved temperature uniformity within ±0.5°C

• Maintained API stability and potency

• Reduced drying time by 30%

• Met all GMP compliance standards

Project Challenge:

The facility required an industrial drying oven for premium herbs and spices, ensuring color retention, flavor preservation, and optimal moisture content for extended shelf life.

Project Results:

• Maintained 95% color retention

• Preserved essential oil content

• Achieved uniform moisture content of 8%

• Extended shelf life by 200%

Project Challenge:

The plant needed a hot air circulation oven for specialty catalyst drying, requiring precise temperature control and contamination-free processing for high-value chemical products.

Project Results:

• Achieved zero contamination

• Maintained catalyst activity at 99.8%

• Reduced energy consumption by 35%

• Improved product consistency by 40%

Comprehensive Service Support for CT-C Hot Air Circulation Oven

From consultation to maintenance, ensuring optimal performance throughout your industrial drying oven lifecycle.

Hot Air Oven Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom hot air circulation oven design services tailored to your specific pharmaceutical and industrial drying requirements.

Professional Installation & Validation

Experienced installation team ensures proper industrial drying oven setup and commissioning. Complete GMP validation documentation and operator training enable maximum productivity from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your pharmaceutical hot air oven. 24/7 technical support keeps operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve hot air circulation oven efficiency. Regular performance assessments ensure sustained optimal operation and compliance.