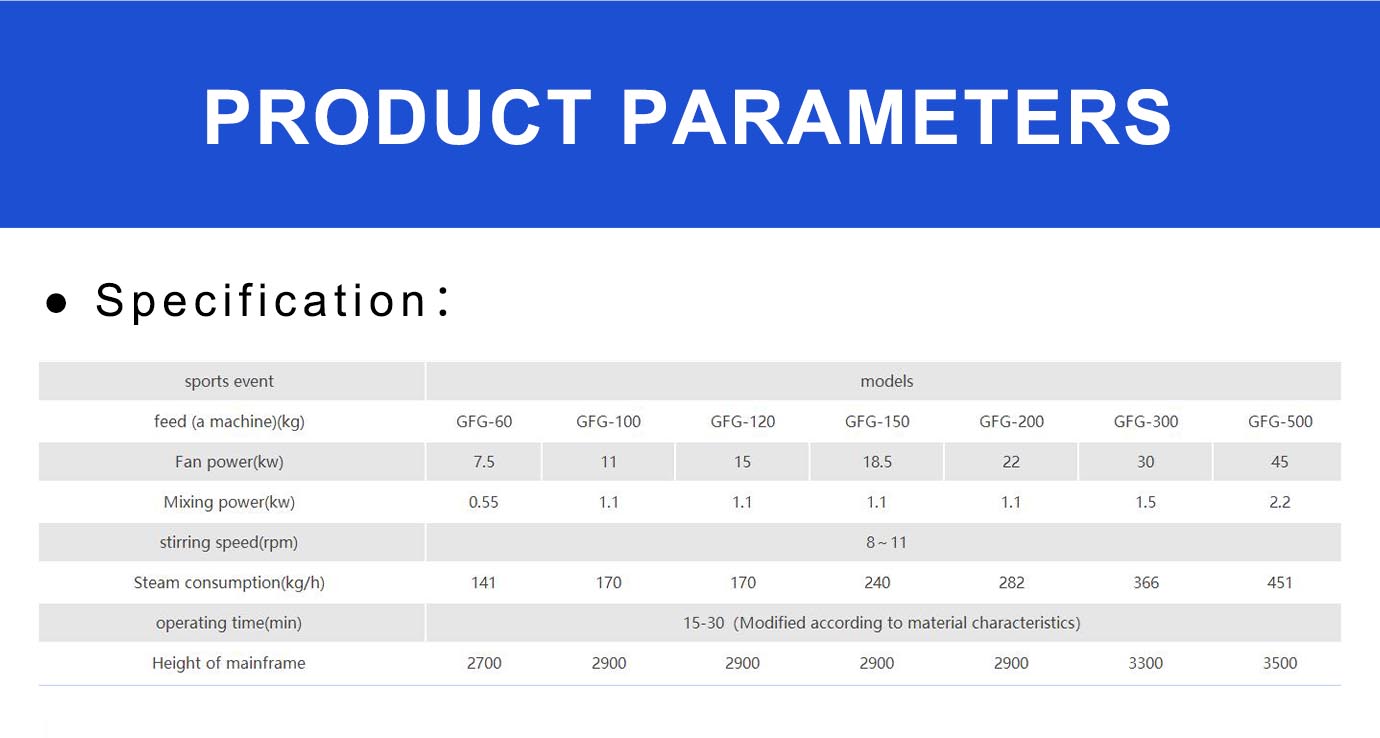

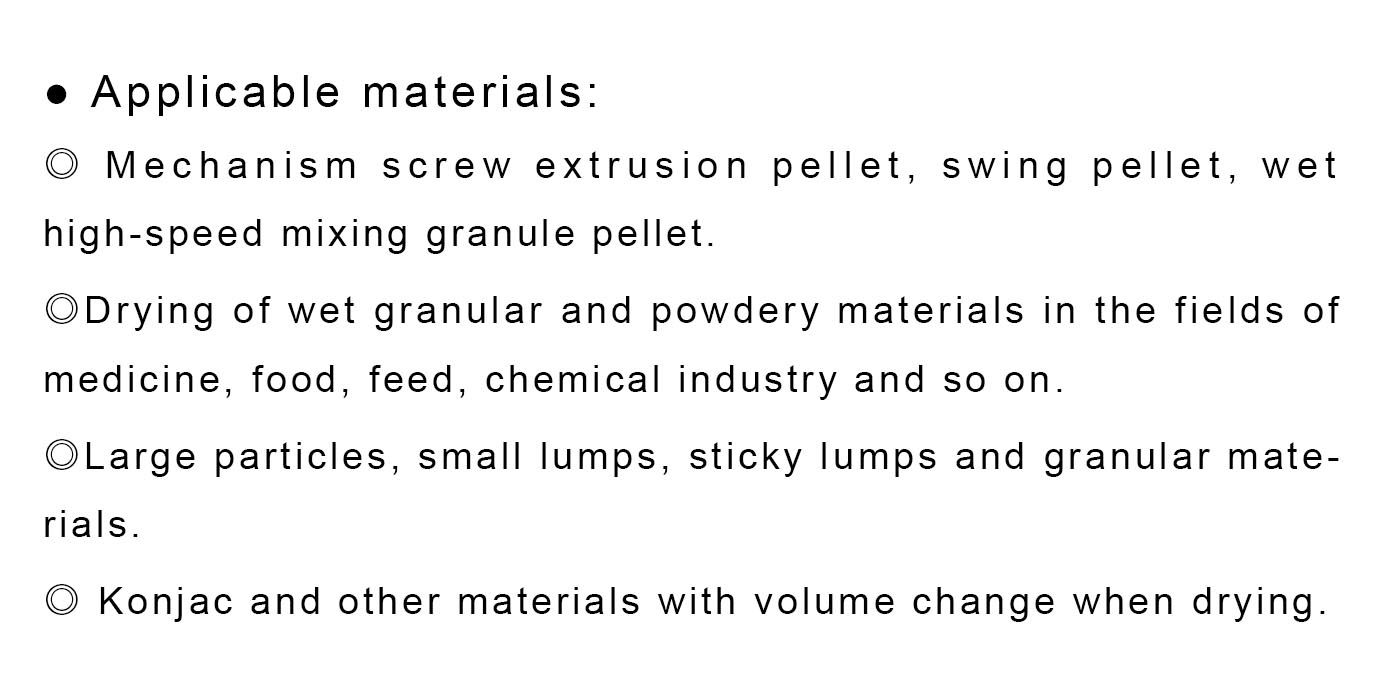

GFG Series High Efficiency Boiling Drying Equipment

Experience superior fluidized bed drying performance with our GFG Series High Efficiency Boiling Drying Equipment. This advanced industrial boiling dryer features high efficiency technology and precise temperature control, delivering exceptional moisture removal for pharmaceutical, chemical, food, and granular material processing with energy-efficient operation and uniform drying results.

Working Principle of GFG High Efficiency Boiling Dryer

Understand the advanced fluidized bed drying technology of our GFG Series Industrial Boiling Drying Equipment, ensuring optimal moisture removal and efficient material processing through high efficiency boiling technology.

Advanced Technical Features of GFG Industrial Boiling Dryer

Delivering superior performance through innovative high efficiency design, precise fluidization control, and energy-efficient operation for boiling drying applications.

High Efficiency Fluidization

Features advanced fluidization technology for optimal heat and mass transfer efficiency. The GFG high efficiency boiling dryer ensures uniform particle mixing and consistent drying performance while minimizing energy consumption.

Precise Temperature Control

Equipped with advanced temperature control systems providing uniform heat distribution throughout the drying chamber. The industrial boiling dryer maintains optimal drying conditions and prevents product overheating.

Optimized Air Distribution

Incorporates specially designed air distribution systems ensuring uniform fluidization across the entire bed. The boiling drying equipment provides consistent particle movement and heat transfer efficiency.

Dust Collection Systems

Features integrated dust collection and filtration systems for environmental protection and product recovery. The high efficiency drying machine captures fine particles while maintaining clean exhaust emissions.

Energy Recovery Technology

Designed with heat recovery systems for maximum energy efficiency and operational cost reduction. The GFG boiling dryer optimizes thermal energy utilization while maintaining superior drying performance.

Versatile GFG High Efficiency Boiling Dryer Applications

From pharmaceutical granules to food processing, our GFG industrial boiling drying equipment delivers exceptional results across diverse fluidized bed drying applications.

Pharmaceutical Industry

Ideal for pharmaceutical granule drying, tablet coating, and drug intermediate processing. Our pharmaceutical boiling dryer ensures gentle processing while maintaining product integrity and meeting regulatory standards.

Chemical Processing

Perfect for chemical powder drying, catalyst processing, and specialty chemical manufacturing. The chemical boiling drying equipment provides precise control over drying conditions for sensitive materials.

Food Processing

Excellent for food granule drying, seasoning processing, and food ingredient manufacturing. The food boiling dryer maintains product quality while achieving optimal moisture content for storage.

Granular Materials

Superior for granular material drying, pellet processing, and bulk material handling. The granular material dryer provides uniform drying results while maintaining particle integrity and flowability.

Exceptional Value from GFG Industrial Boiling Dryer

Maximize production efficiency, energy savings, and product quality with our advanced high efficiency boiling drying technology.

Enhanced Drying Efficiency

The GFG high efficiency boiling dryer achieves superior drying performance through optimized fluidization and heat transfer. This industrial boiling drying equipment significantly reduces processing time while maintaining consistent product quality.

Cost-Effective Operation

Energy recovery systems and optimized airflow design minimize operational costs. The boiling drying equipment reduces energy consumption through efficient thermal management and automated operation controls.

Uniform Product Quality

Fluidized bed technology ensures uniform heat distribution and consistent drying results. The high efficiency drying machine maintains product specifications while preventing over-drying or under-drying issues.

Versatile Processing Capabilities

Accommodates various granular materials and moisture contents with adjustable operating parameters. The GFG boiling dryer adapts to different processing requirements and material characteristics with ease.

Success Stories: GFG High Efficiency Boiling Dryer in Action

Partnering with leading companies to achieve excellence in fluidized bed drying with our advanced industrial boiling drying solutions.

Project Challenge:

The client needed a pharmaceutical boiling dryer for large-scale granule processing that could achieve uniform moisture content while maintaining particle integrity and meeting GMP requirements.

Project Results:

• Achieved ±0.2% moisture uniformity

• Maintained 99% particle integrity

• Reduced processing time by 45%

• Met all GMP compliance standards

Project Challenge:

The facility required a chemical boiling drying equipment for catalyst processing that could provide gentle drying while maintaining catalyst activity and achieving precise moisture specifications.

Project Results:

• Preserved 98% catalyst activity

• Achieved target moisture content

• Improved product uniformity by 40%

• Enhanced production efficiency by 35%

Project Challenge:

The company needed a food boiling dryer for seasoning granule processing that could maintain flavor integrity while achieving consistent moisture content for extended shelf life.

Project Results:

• Maintained 95% flavor retention

• Achieved consistent moisture levels

• Extended shelf life by 50%

• Improved product flowability significantly

Comprehensive Service Support for GFG Industrial Boiling Dryer

From consultation to maintenance, ensuring optimal performance throughout your boiling drying equipment lifecycle.

Boiling Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial boiling dryer design services tailored to your specific material properties and high efficiency drying requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper GFG boiling dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the boiling drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your high efficiency drying machine. 24/7 technical support keeps fluidized bed drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve high efficiency boiling dryer performance. Regular assessments ensure sustained optimal operation and compliance with industry standards.