Closed Circuit Centrifugal Spray Dryer

Experience superior centrifugal spray drying and solvent recovery with our Closed Circuit Centrifugal Spray Dryer. This advanced industrial centrifugal spray drying equipment features closed loop technology and efficient centrifugal spray drying capabilities, delivering exceptional performance for pharmaceutical, chemical, food, and powder processing with efficient solvent recovery and environmental protection.

Working Principle of Closed Circuit Centrifugal Spray Dryer

Understand the advanced closed loop centrifugal spray drying technology of our Industrial Centrifugal Spray Drying Equipment, ensuring optimal solvent recovery and environmental protection through efficient centrifugal spray drying technology.

Advanced Technical Features of Closed Circuit Centrifugal Spray Dryer

Delivering superior performance through innovative closed loop design, efficient centrifugal atomization, and environmental protection for spray drying applications.

Closed Loop Technology

Features advanced closed circuit design for complete solvent recovery and zero emissions operation. The closed loop spray dryer ensures environmental compliance while maximizing solvent reuse efficiency and operational cost savings.

Centrifugal Atomization

Incorporates high-speed centrifugal atomizer for precise droplet formation and uniform particle size distribution. The industrial centrifugal spray drying equipment provides superior atomization performance while reducing energy consumption.

Solvent Recovery Systems

Equipped with advanced condensation and recovery systems for maximum solvent reclamation. The centrifugal spray drying equipment achieves high solvent recovery efficiency with automated operation controls.

Precise Particle Control

Designed for precise particle size control and uniform product quality. The closed circuit centrifugal spray dryer maintains optimal processing conditions while achieving excellent particle characteristics and product specifications.

Environmental Protection

Features comprehensive emission control and environmental protection systems. The environmental spray dryer eliminates solvent emissions while meeting strict environmental regulations and sustainability requirements.

Versatile Closed Circuit Centrifugal Spray Dryer Applications

From pharmaceutical powders to food ingredients, our closed loop centrifugal spray drying equipment delivers exceptional results across diverse powder production applications.

Pharmaceutical Industry

Ideal for pharmaceutical powder production, API processing, and drug formulation manufacturing. Our pharmaceutical centrifugal spray dryer ensures precise particle control while maintaining product purity and meeting regulatory standards.

Chemical Processing

Perfect for chemical powder production, catalyst manufacturing, and specialty chemical processing. The chemical centrifugal spray drying equipment provides efficient solvent recovery with environmental protection.

Food Processing

Excellent for food powder production, dairy processing, and beverage ingredient manufacturing. The food centrifugal spray dryer maintains product quality while achieving optimal particle characteristics and nutritional preservation.

Material Processing

Superior for various powder production requiring precise particle control and uniform quality. The powder centrifugal spray dryer provides consistent processing results while maintaining material integrity and product specifications.

Exceptional Value from Closed Circuit Centrifugal Spray Dryer

Maximize powder quality, solvent recovery, and environmental compliance with our advanced closed loop centrifugal spray drying technology.

Precise Particle Control

The closed circuit centrifugal spray dryer achieves precise particle size control and uniform product quality. This industrial centrifugal spray drying equipment provides superior particle characteristics while maintaining consistent product specifications.

Superior Solvent Recovery

Advanced recovery systems capture and recycle valuable solvents with high efficiency. The closed loop spray dryer provides excellent solvent recovery while reducing environmental impact and operational costs.

Enhanced Production Efficiency

Centrifugal atomization technology ensures rapid drying and high production rates. The centrifugal spray drying machine provides superior processing efficiency while maintaining optimal product quality and consistency.

Environmental Compliance

Zero emissions operation ensures complete environmental compliance and sustainability. The closed circuit centrifugal spray dryer eliminates solvent emissions while meeting strict environmental regulations and corporate sustainability goals.

Success Stories: Closed Circuit Centrifugal Spray Dryer in Action

Partnering with leading companies to achieve excellence in centrifugal spray drying and environmental protection with our advanced closed loop drying solutions.

Project Challenge:

The client needed a pharmaceutical centrifugal spray dryer for API powder production that could achieve precise particle control while maintaining product purity and achieving high solvent recovery rates with environmental compliance.

Project Results:

• Achieved 99% solvent recovery efficiency

• Maintained API purity above 99.9%

• Achieved precise particle size control

• Reduced production costs by 30%

Project Challenge:

The facility required a chemical centrifugal spray drying equipment for specialty chemical manufacturing that could handle heat-sensitive materials while achieving maximum solvent recovery and environmental protection.

Project Results:

• Processed heat-sensitive materials safely

• Achieved 97% solvent recovery

• Met all environmental standards

• Improved product quality consistency

Project Challenge:

The company needed a food centrifugal spray dryer for dairy powder production that could maintain nutritional value while achieving optimal particle characteristics and meeting food safety standards.

Project Results:

• Maintained nutritional value and quality

• Achieved optimal particle characteristics

• Met all food safety requirements

• Enhanced product solubility significantly

Comprehensive Service Support for Closed Circuit Centrifugal Spray Dryer

From consultation to maintenance, ensuring optimal performance throughout your industrial centrifugal spray drying equipment lifecycle.

Centrifugal Spray Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom closed circuit centrifugal spray dryer design services tailored to your specific solvent recovery and environmental protection requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper closed loop spray dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the centrifugal spray drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your industrial centrifugal spray drying equipment. 24/7 technical support keeps spray drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve closed circuit centrifugal spray dryer performance. Regular assessments ensure sustained optimal solvent recovery and environmental compliance.

summary:

The closed cycle centrifugal spray drying equipment is a closed circulation loop formed by the system, and the heat carrier can be recycled. For the drying of volatile organic solvents, toxic or hazardous materials that can cause harm to people and the environment after release, the organic solvents or products contained in the liquid are easily oxidized, flammable, and explosive materials. In general, materials that require this process cannot come into contact with oxygen, so most heat carriers use inert gases (such as nitrogen, carbon dioxide, etc.); This method is also known as inert gas drying. The exhaust gas discharged from the dryer, after gas-solid separation, also needs to go through a condenser to recover solvents or remove moisture, and then enter the dryer for recycling after being heated by a heater. Through the heat carrier and closed cycle, we can effectively avoid the danger of high temperature when drying materials, prevent contact with oxygen during spray drying, and recover more than 90% of dust.

The closed cycle spray drying machine has been successfully applied to the closed cycle spray drying process for the suspension made of ethanol, acetone, cyclohexane, toluene and other organic solvents, and the products with inert gas (or nitrogen) as the drying medium. The entire process is oxidation free, the medium is recyclable, and the inert gas (or nitrogen) can be recycled. The closed cycle system designed for organic solvent recovery has extremely high requirements for explosion-proof control and high self-control performance. It is commonly used for spray drying of precision ceramics, pharmaceuticals, battery materials, hard alloy (Wc. Fe) powder.

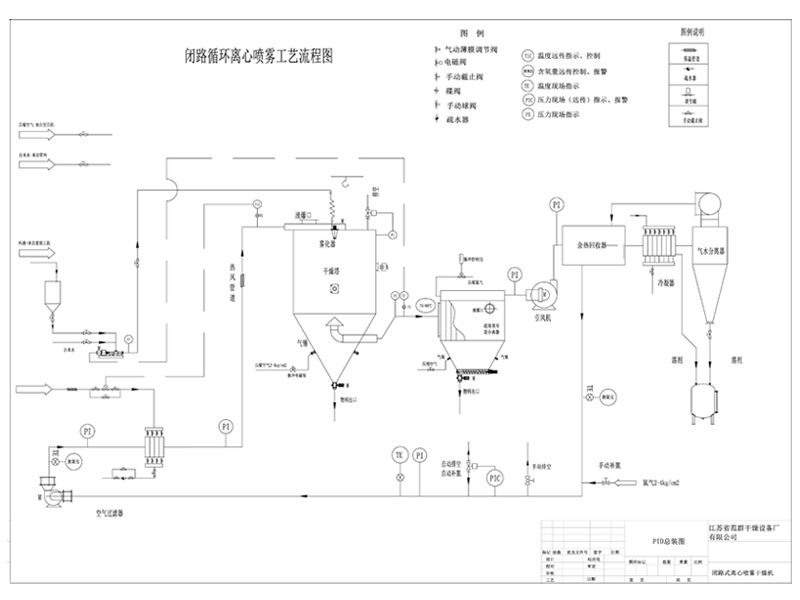

Working principle of closed cycle centrifugal spray dryer

The explosion-proof closed circuit centrifugal spray dryer system consists of the main engine of the centrifugal spray dryer, air filter, heater, primary cyclone separator, secondary cyclone separator, pump, exhaust fan, condenser, oxygen detector, pipeline and control valve.

Working principle: Firstly, heated nitrogen gas is filled into the drying tower, and the dried liquid material is transported to the centrifugal nozzle through an infusion pump. The liquid material is atomized into small droplets by a high-speed rotating centrifugal atomizer, and the droplets undergo sufficient heat exchange with the hot nitrogen gas in the drying tower. The liquid part of the material is instantly evaporated, and the solid part forms a powder material that settles at the bottom of the tower. Finally, the dried powder material is discharged from the bottom of the tower. Among them, the evaporated organic solvent gas is subjected to dust removal treatment by devices such as cyclone separator and bag filter under the action of the fan, and then the saturated organic solvent gas after dust removal is condensed into liquid and discharged from the condenser. During this process, the inert gas used as a drying medium is continuously heated and reused as a drying carrier within the system.

The explosion-proof closed circulation centrifugal spray drying system works in a closed environment. The drying medium is inert gas such as nitrogen. The drying tower is operated under positive pressure. If the internal pressure drops, the pressure transmitter can automatically control the nitrogen inflow to ensure the system pressure balance. Using nitrogen as a circulating carrier has a protective effect on dry materials. Nitrogen and other circulating carriers play a role in carrying, removing, and circulating moisture, and their carrier media can be reused. However, conventional conventional centrifugal spray drying achieves the purpose of moisture removal through continuous air supply and exhaust, and its tower is controlled by negative pressure operation, which is also the obvious difference between explosion-proof closed centrifugal spray drying system and conventional centrifugal spray drying system. Therefore, the explosion-proof closed cycle centrifugal spray drying system is particularly suitable for drying organic solvent materials, toxic gas materials and materials prone to oxidation in the drying process.

Process Flow Diagram of Closed Cycle Centrifugal spray Dryer equipment

Closed loop centrifugal spray drying equipment new technology theory

1、The closed-circuit system is applied to the explosion-proof centrifugal spray dryer, and it is the first one to be applied in the industrial mass production;

2、The application of differential pressure automatic transmission and online oxygen detection technology makes the system safer and the product quality more guaranteed;

3、The application of intelligent automatic control technology upgrades the traditional centrifugal spray drying equipment;

4、Innovation of no-leakage technology, effectively solving the leakage problem of such systems.

Closed loop centrifugal spray dryer advantages embodiment

1、Closed-circuit centrifugal spray dryer adopts nitrogen as the heat transfer medium and nitrogen as the carrier to realize closed-circuit circulation under the state of airtightness, which effectively achieves the safety of drying liquid materials containing organic solvents and the protection of anti-oxidation for easily oxidizable wet materials in the process of drying and production process.

2, the unit adopts new spray drying technology, so as to realize the traditional centrifugal spray drying incomparable to the high solid content, and has a viscous, thick liquid material nitrogen power atomization, so as to improve production capacity and reduce energy consumption by more than 70%, to achieve the obvious energy saving and high yield production effect.

3、This unit adopts online monitoring and self-diagnosis control function to ensure the safe production of drying liquid materials containing organic solvents, and the intelligent control system has a high degree of automation.

4、This unit realizes the recycling of organic solvent-containing materials in the drying production process, and solves the problem of difficult drying and heavy pollution of exhaust gas emission in related industries, and realizes the recycling of solvents, and obtains the practical effect of energy saving and emission reduction.