Closed Circuit Boiling Drying Equipment

Experience superior boiling drying and solvent recovery with our Closed Circuit Boiling Drying Equipment. This advanced industrial boiling dryer features closed loop technology and efficient boiling drying capabilities, delivering exceptional performance for pharmaceutical, chemical, food, and powder processing with efficient solvent recovery and environmental protection.

Working Principle of Closed Circuit Boiling Drying Equipment

Understand the advanced closed loop boiling drying technology of our Industrial Boiling Dryer, ensuring optimal solvent recovery and environmental protection through efficient boiling drying technology.

Advanced Technical Features of Closed Circuit Boiling Drying Equipment

Delivering superior performance through innovative closed loop design, efficient boiling technology, and environmental protection for industrial drying applications.

Closed Loop Technology

Features advanced closed circuit design for complete solvent recovery and zero emissions operation. The closed loop boiling dryer ensures environmental compliance while maximizing solvent reuse efficiency and operational cost savings.

Boiling Fluidization

Incorporates intensive boiling fluidization for enhanced heat transfer and mixing. The industrial boiling dryer provides superior particle fluidization and uniform drying performance while reducing energy consumption.

Solvent Recovery Systems

Equipped with advanced condensation and recovery systems for maximum solvent reclamation. The boiling drying equipment achieves high solvent recovery efficiency with automated operation controls.

Uniform Processing

Designed for uniform material processing ensuring consistent product quality. The closed circuit boiling drying equipment maintains optimal processing conditions while achieving excellent heat and mass transfer efficiency.

Environmental Protection

Features comprehensive emission control and environmental protection systems. The environmental boiling dryer eliminates solvent emissions while meeting strict environmental regulations and sustainability requirements.

Versatile Closed Circuit Boiling Drying Equipment Applications

From pharmaceutical powders to chemical processing, our closed loop boiling drying equipment delivers exceptional results across diverse solvent recovery applications.

Pharmaceutical Industry

Ideal for pharmaceutical powder drying, API processing, and drug intermediate manufacturing. Our pharmaceutical boiling dryer ensures gentle processing while maintaining product purity and meeting regulatory standards.

Chemical Processing

Perfect for chemical powder drying, fine chemical processing, and specialty chemical manufacturing. The chemical boiling drying equipment provides efficient solvent recovery with environmental protection.

Food Processing

Excellent for food powder drying, ingredient processing, and specialty food manufacturing. The food boiling dryer maintains product quality while achieving optimal moisture content and flowability.

Material Processing

Superior for various powder and granular material processing requiring uniform drying. The powder boiling dryer provides consistent drying results while maintaining particle integrity and product specifications.

Exceptional Value from Closed Circuit Boiling Drying Equipment

Maximize drying efficiency, solvent recovery, and environmental compliance with our advanced closed loop boiling drying technology.

Enhanced Drying Efficiency

The closed circuit boiling drying equipment achieves superior drying performance through optimized boiling fluidization. This industrial boiling dryer significantly reduces processing time while maintaining consistent product quality.

Superior Solvent Recovery

Advanced recovery systems capture and recycle valuable solvents with high efficiency. The closed loop boiling dryer provides excellent solvent recovery while reducing operational costs and environmental impact.

Uniform Product Quality

Boiling fluidization technology ensures uniform processing and consistent product quality. The boiling drying machine maintains optimal processing conditions while achieving excellent moisture removal and product uniformity.

Environmental Compliance

Zero emissions operation ensures complete environmental compliance and sustainability. The closed circuit boiling dryer eliminates solvent emissions while meeting strict environmental regulations and corporate sustainability goals.

Success Stories: Closed Circuit Boiling Drying Equipment in Action

Partnering with leading companies to achieve excellence in boiling drying and environmental protection with our advanced closed loop drying solutions.

Project Challenge:

The client needed a pharmaceutical boiling dryer for API processing that could achieve uniform drying while maintaining product purity and achieving high solvent recovery rates with environmental compliance.

Project Results:

• Achieved 98% solvent recovery efficiency

• Maintained API purity above 99.8%

• Achieved zero solvent emissions

• Reduced processing time by 30%

Project Challenge:

The facility required a chemical boiling drying equipment for fine chemical processing that could handle heat-sensitive materials while achieving maximum solvent recovery and environmental protection.

Project Results:

• Processed heat-sensitive materials safely

• Achieved 96% solvent recovery

• Met all environmental standards

• Improved product quality consistency

Project Challenge:

The company needed a food boiling dryer for specialty food processing that could maintain product integrity while achieving optimal moisture content and meeting food safety standards.

Project Results:

• Maintained product integrity and quality

• Achieved optimal moisture content

• Met all food safety requirements

• Enhanced product flowability significantly

Comprehensive Service Support for Closed Circuit Boiling Drying Equipment

From consultation to maintenance, ensuring optimal performance throughout your industrial boiling drying equipment lifecycle.

Boiling Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom closed circuit boiling drying equipment design services tailored to your specific solvent recovery and environmental protection requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper closed loop boiling dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the boiling drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your industrial boiling dryer. 24/7 technical support keeps boiling drying operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve closed circuit boiling drying equipment performance. Regular assessments ensure sustained optimal solvent recovery and environmental compliance.

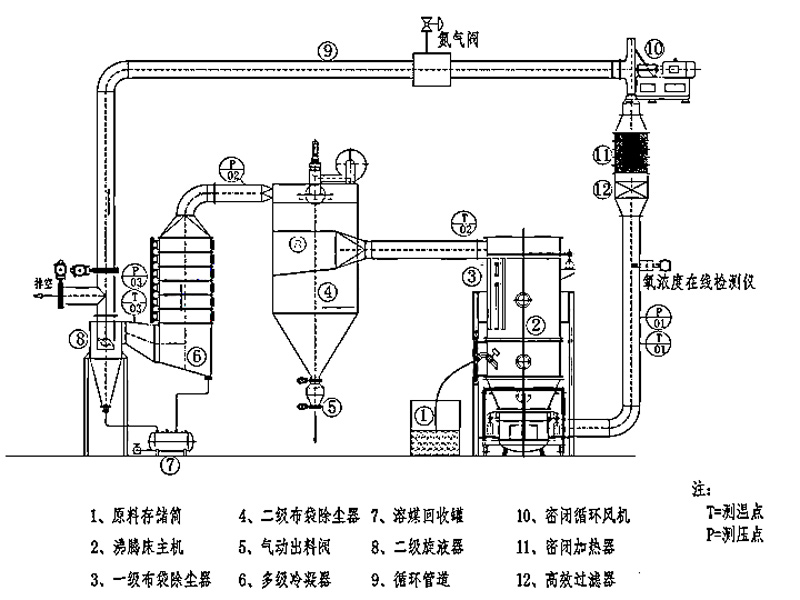

Principle of Closed Loop Boiling Dryer

The closed-circuit boiling dryer is a closed-loop system. At the beginning, start the fan, open the exhaust valve, close the switching valve, input inert gas (generally nitrogen), the original air in the system replacement, when the oxygen content in the system reaches a predetermined target, close the valve exhaust valve, open the switching valve. Nitrogen in the system as a medium for heat and mass transfer to complete the drying of wet materials. Wet materials containing organic solvent gasification, with nitrogen into the condenser, the solvent condensed into liquid into the tank, nitrogen due to the lower boiling point is not possible to liquefy, driven by the fan into the next round of circulation. The drying device in the closed-circuit vibrating fluidized bed dryer system can be selected according to the state of the material and the requirements of the cylindrical boiling dryer (also known as high-efficiency boiling), or box-type boiling dryer, or vibrating fluidized bed dryer, or even air dryer, because these dryers are fluidized drying, so the drying rate is higher, the drying time of the material is short.

Closed-circuit boiling dryer features

1、System is fully closed, basically no oxygen (content self-control). As mentioned above, the closed-loop boiling dryer system is in a fully closed state operation, neither (nor allowed) to leak outward, nor (not allowed) to leak inward. For this reason, it must be done that all parts of the system, whether it is the pipeline interface, or the box inlet and outlet; whether in the positive pressure zone, or negative pressure zone; whether it is static parts or dynamic parts, must be strictly sealed. Oxygen content in the system does not exceed the process requirements, to ensure the safety of explosion-proof and flame-proof, but also to provide a reliable guarantee of oxygen-fearing materials.

2, zero emissions. If the system is a continuous operation, there is basically no exhaust emissions.

3、Solvent recovery. If the system can work continuously, the solvent recovery rate is very high (up to 98% or more), and its economic significance is self-evident.

4、High degree of automation. Our company has set up the automatic control of three parameters such as temperature, oxygen content, system pressure and over-limit alarm device in the system, which is controlled by PLC, easy to operate, safe and reliable.

Application scope of closed-circuit boiling dryer

Granulation in pharmaceutical industry: tablet granule, punch granule, capsule granule.

Granulation in food industry: cocoa, coffee, milk powder, granule juice, flavorings, etc.

Other industry granulation: pesticide, feed, fertilizer, pigment, dyes and chemicals.

Drying of powder or granular wet materials.

Coating: granule, pill protective layer, color preparation, slow release, film, enteric coating, etc.

Closed Circuit Boiling Dryer Equipment Technical Description

Closed-circuit boiling dryer is composed of drying mainframe, heater, condenser, cloth bag dust collector, fan and material bin. The whole drying process is carried out in a closed environment under the protection of nitrogen, and the discharging is carried out in a closed environment, which is characterized by no dust and high safety.

Before using the closed-circuit boiling dryer, nitrogen is used to replace the air in the system so that the oxygen content in the system reaches the safe concentration of solvent. The wet material is in the closed container and enters into the drying main machine by the feeding port on the equipment. The blower sends in the filtered nitrogen gas, which is heated by the heater to the temperature required for the drying process, and then enters the boiling bed to carry out heat and mass transfer (drying) on the material added by the bit difference feeding port, and then dries to the final humidity required for the material after the feeding is completed. Closed loop boiling dryer in the drying process, hot and humid gas with a small number of micro-powder through the dust collector will be all 2um above the micro-powder in the dust collector for gas-solid separation. The solid dust is collected in the dust collector, and the gas enters the multi-stage condenser (finned condenser with small pressure drop and good condensing effect) to condense the solvent inside the hot and humid gas. The condensed solvent is collected in a collection tank and stored (zero emission into the air, recyclable). The dried nitrogen gas after condensation and dehumidification is then sent to the heater for recycling through the blower. The materials after drying of the closed-circuit boiling dryer are put into the lower cylinder by the flap mechanism on the hot air distribution board, and then fed into the airtight container for storing and dispensing through the vacuum pump or airflow conveying system (the inlet and outlet of the materials are all operated in an airtight environment, and there is no dust in the workshop).

Advantages of Closed Circuit Boiling Dryer

1、After drying by the closed-circuit boiling dryer, the hot and humid gas containing solvent enters the condenser to condense the solvent in the gas (solvent recovery rate of more than 95%), which can not only recycle the solvent, but also condense the dehumidified dry gas. The recovered solvent can be recycled again, which can save cost and at the same time will not cause the exhaust emission to the environment. After condensing and dehumidifying the hot and humid gas, the absolute humidity within the gas is low (compared with the ordinary boiling drying), the drying ability becomes stronger, more adaptable to the humidity environment and easy to absorb moisture materials.

2、Closed-circuit boiling dryer is fully enclosed structure, the equipment is filled with inert gas (such as nitrogen), in the drying of anaerobic materials or solvents containing flammable and explosive nature of the material, so that there is no oxygen in the gas, can not be combusted or oxidized, the equipment can be effectively avoided in the production of fire or explosion accidents, so it is safer than ordinary equipment.

3, closed-loop boiling dryer work inside the required wind pressure is low, only need to micro-positive pressure, so the equipment with the fan power to reduce, because in the positive pressure when the hot air is blown upward from the lower part of the hopper mesh plate, the wind's penetration is strong, although the material boiling height is not high, but the hot air and the material is more fully in contact with the drying rate is faster. After the power of the fan of the equipment is reduced, the noise of the equipment becomes smaller, and also saves energy.

4, closed loop boiling dryer with flap mechanism, realized in the fully enclosed conditions for discharging, greatly reducing the labor intensity of workers and the operation of the workshop is completely free of dust, the workshop environment is good, high degree of automation.

5, closed loop boiling dryer host use pulse dust removal system, dust removal efficiency is high, dust is not bonded with the filter cartridge, easy to disassemble, clean.

Closed Circuit Boiling Dryer Equipment Features and Advantages

Safety

Closed-circuit boiling dryer is a fully enclosed structure, the equipment is filled with nitrogen, in drying anaerobic materials or materials containing flammable and explosive solvents, so that there is no oxygen in the gas, unable to combust or oxidize, can effectively avoid the equipment in the production of fire or explosion accidents, so it is safer than ordinary equipment.

High efficiency

Closed-circuit boiling dryer host uses bag pulse dust removal system, high dust removal efficiency, dust is not bonded with the filter cartridge, easy to disassemble and clean. And the use of the whole machine blowback technology (patented technology) in the closed-loop boiling dryer drying equipment for the whole machine after the completion of the counter-attack, the dust thoroughly, the use of this technology after the equipment bag cleaning frequency from the original 1-2 days a wash to extend to 12-15 days a wash. Closed-circuit boiling dryer in the lower part of the host out of the section, can be pumped by the vacuum discharge to the material storage device, reduce the intensity of worker operation, improve efficiency.

Environmental protection

After drying by the closed-loop boiling dryer, the hot humid gas containing solvent enters the condenser to condense the solvent in the gas (solvent recovery rate of more than 95%), which can not only recover the solvent but also condense the dehumidified dry gas. The recovered solvent can be recycled again, which can save cost and at the same time will not cause the exhaust emission to the environmental pollution.

Energy saving

Closed-circuit boiling dryer work inside the required air pressure is low, only need to micro-positive pressure, so the equipment with the fan power to reduce, because in the positive pressure when the hot air is blown upward from the lower part of the hopper mesh plate, the wind's penetration is strong, although the material boiling height is not high, but the hot air and the material is more fully in contact with the drying rate is faster. After the power of the fan of the equipment is reduced, the noise of the equipment becomes smaller, and also saves energy.

Wide spectrum

The hot and humid gas inside the closed-circuit boiling dryer is condensed and dehumidified, and the absolute humidity inside the gas is low, and the drying ability becomes stronger, which is more suitable for the moisture-absorbing materials that are sensitive to the humidity environment. For materials with fine particles: due to the low wind pressure, the escape rate of materials is small, and can be fully recovered in the secondary dust removal.

Closed loop boiling dryer in the drying process for fluidization, materials and hot air for large area gas-solid contact, drying intensity, high efficiency, and with the increase in equipment, equipment fan air volume increases, the use of equipment efficiency can still be guaranteed; not like static vacuum drying system, with the increase in equipment, its drying efficiency is getting lower and lower. Closed loop boiling dryer drying process of the material for the fluidization, to avoid the vacuum drying system in the material heating surface and direct contact with the material caused by the local material overheating deterioration and other undesirable conditions.

Closed Circuit Boiling Dryer Process Flow Diagram

Closed Circuit Boiling Dryer Equipment Structure

Closed loop boiling dryer consists of air filter, air heater, drying bed, separation room, filtration room, air duct, circulating fan, control system and so on.

1、Main machine: the main machine consists of bottom section air inlet room, drying bed, separation room and filtration room.

2、Air filter: It is filtered by primary and secondary air filters to ensure the cleanliness of air inlet.

3、Air heater: It adopts stainless steel tube around fins, which improves the heat transfer coefficient of the heat exchanger under the circumstance of ensuring that no rusty foreign matter is dislodged.

4、Exhaust air system

It consists of air exhaust pipe, circulating fan and isolated installation with main machine, the noise is ≤80dB, the air volume can be adjusted by frequency conversion, and the fluidization state can be adjusted continuously, thus this machine is suitable for a wide range of feeding, and it can also be adapted well to the requirements of air volume of different material conditions.

5、Mixing organization

Adopting the built-in rake tooth stirring mechanism of material car, it can assist the fluidization, prevent the dead bed phenomenon of ditch flow of material in the drying process, keep the fluidization state stable, and the moisture content of material after drying is uniform.

Technical characteristics of closed-circuit boiling dryer

1、PLC-touch screen operation, easy to operate, stable, with strict interlock function, will not lead to human misoperation.

2、Dust-cleaning method is pulse bag dust-cleaning, continuous offline dust-cleaning and dust-removing when working. The effect of ash removal is far better than the cylinder shaking bag ash removal method, avoiding the dead bed of materials when drying.

3、Configuration of the upper draw type hard skeleton bag, in order to ensure the area of the bag and the effect of dust cleaning at the same time, reduce the workers in the dismantling and cleaning of the bag, the characteristics of the working environment is poor. In the case that people don't need to drill into the cylinder, it is easy to remove the cloth bag from the equipment.

4、Boiling Drying Equipment through the automatic discharging device, to achieve automatic closed discharging, reduce the cross-pollution of materials and workers labor intensity.

5、Boiling Drying Equipment contains stirring structure, which can prevent material bridging and dead bed. Make the material fluidization boiling drying effect is better.

6、Boiling Drying Equipment adopts closed circular structure, no dead angle, easy and quick cleaning, no cross contamination.

7、After docking with pneumatic conveying system, it can realize the function of unmanned automatic continuous operation (optional).

8, at the bottom of the host is equipped with a sewage device, can quickly drain the washing machine when the water;

9、The whole machine is easy to operate, easy to disassemble and easy to clean;

10, the whole machine is well sealed, negative pressure operation

11, pulse bag filter filtration (or stainless steel blowback filter can be used when there are special requirements) and has a differential pressure detection function to ensure reliable sealing. Exhaust duct design temperature sensor, and interlocked with PLC control system to ensure product safety in the production process.