Closed Circuit Rotary Flash Dryer

Experience superior solvent recovery and environmental protection with our Closed Circuit Rotary Flash Dryer. This advanced industrial flash drying equipment features closed loop technology and rotary flash drying capabilities, delivering exceptional performance for pharmaceutical, chemical, food, and powder processing with efficient solvent recovery and zero emissions operation.

Working Principle of Closed Circuit Rotary Flash Dryer

Understand the advanced closed loop flash drying technology of our Industrial Flash Drying Equipment, ensuring optimal solvent recovery and environmental protection through rotary flash drying technology.

Advanced Technical Features of Closed Circuit Rotary Flash Dryer

Delivering superior performance through innovative closed loop design, efficient solvent recovery, and environmental protection for industrial flash drying applications.

Closed Loop Technology

Features advanced closed circuit design for complete solvent recovery and zero emissions operation. The closed loop flash dryer ensures environmental compliance while maximizing solvent reuse efficiency and operational cost savings.

Rotary Flash Drying

Incorporates high-speed rotating mechanism for intensive heat and mass transfer. The rotary flash drying machine provides rapid moisture removal while maintaining product quality and preventing thermal degradation.

Solvent Recovery Systems

Equipped with advanced condensation and recovery systems for maximum solvent reclamation. The industrial flash drying equipment achieves up to 99% solvent recovery efficiency with automated operation controls.

Inert Gas Operation

Designed for inert gas operation ensuring safe processing of flammable solvents. The closed circuit rotary flash dryer provides explosion-proof operation with comprehensive safety monitoring systems.

Environmental Protection

Features comprehensive emission control and environmental protection systems. The environmental flash dryer eliminates solvent emissions while meeting strict environmental regulations and sustainability requirements.

Versatile Closed Circuit Rotary Flash Dryer Applications

From pharmaceutical intermediates to chemical processing, our closed loop flash drying equipment delivers exceptional results across diverse solvent recovery applications.

Pharmaceutical Industry

Ideal for pharmaceutical intermediate drying, API processing, and drug substance manufacturing. Our pharmaceutical flash dryer ensures solvent recovery while maintaining product purity and meeting regulatory standards.

Chemical Processing

Perfect for chemical intermediate drying, fine chemical processing, and specialty chemical manufacturing. The chemical flash drying equipment provides efficient solvent recovery with environmental protection.

Food & Flavor Industry

Excellent for food extract processing, flavor concentrate drying, and natural product manufacturing. The food flash dryer maintains product integrity while recovering valuable solvents safely.

Solvent-Based Materials

Superior for any solvent-containing material processing requiring recovery and environmental protection. The solvent recovery flash dryer handles various organic solvents with high efficiency and safety.

Exceptional Value from Closed Circuit Rotary Flash Dryer

Maximize solvent recovery, environmental compliance, and operational efficiency with our advanced closed loop flash drying technology.

Superior Solvent Recovery

The closed circuit rotary flash dryer achieves up to 99% solvent recovery efficiency through advanced condensation systems. This industrial flash drying equipment significantly reduces solvent costs while maintaining high product quality.

Environmental Compliance

Zero emissions operation ensures complete environmental compliance and sustainability. The closed loop flash dryer eliminates solvent emissions while meeting strict environmental regulations and corporate sustainability goals.

Cost-Effective Operation

Solvent recovery and reuse dramatically reduce operational costs. The rotary flash drying machine provides rapid return on investment through solvent savings and reduced waste disposal expenses.

Safe Processing

Inert gas operation and explosion-proof design ensure safe processing of flammable solvents. The closed circuit flash dryer provides comprehensive safety features with automated monitoring and control systems.

Success Stories: Closed Circuit Rotary Flash Dryer in Action

Partnering with leading companies to achieve excellence in solvent recovery and environmental protection with our advanced closed loop flash drying solutions.

Project Challenge:

The client needed a pharmaceutical flash dryer for API processing that could achieve high solvent recovery rates while maintaining product purity and meeting strict environmental regulations.

Project Results:

• Achieved 99.2% solvent recovery efficiency

• Maintained API purity above 99.8%

• Achieved zero solvent emissions

• Reduced solvent costs by 85%

Project Challenge:

The facility required a chemical flash drying equipment for fine chemical processing that could handle flammable solvents safely while achieving maximum recovery and environmental compliance.

Project Results:

• Processed flammable solvents safely

• Achieved 98.5% solvent recovery

• Met all environmental standards

• Improved production efficiency by 40%

Project Challenge:

The company needed a food flash dryer for natural extract processing that could recover expensive solvents while maintaining extract quality and meeting food safety standards.

Project Results:

• Maintained extract quality and potency

• Recovered 97% of expensive solvents

• Met all food safety requirements

• Reduced production costs by 60%

Comprehensive Service Support for Closed Circuit Rotary Flash Dryer

From consultation to maintenance, ensuring optimal performance throughout your industrial flash drying equipment lifecycle.

Flash Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom closed circuit rotary flash dryer design services tailored to your specific solvent recovery and environmental protection requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper closed loop flash dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from the industrial flash drying equipment.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your rotary flash drying machine. 24/7 technical support keeps solvent recovery operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve closed circuit flash dryer performance. Regular assessments ensure sustained optimal solvent recovery and environmental compliance.

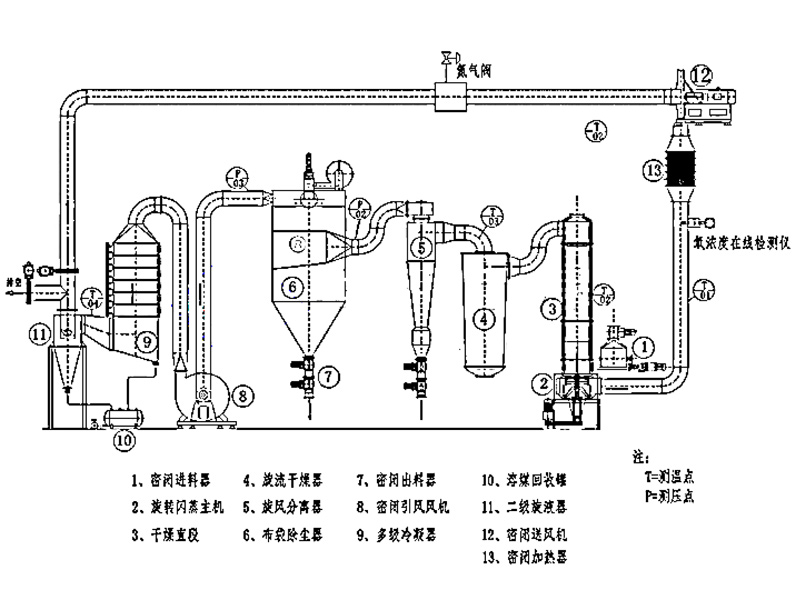

Overview of the dryer

Closed-circuit rotary flash dryer machine consists of drying mainframe, heater, cyclone separator, bag filter condenser, fan and pipeline. The whole drying process is carried out under the condition of very low oxygen content under the protection of nitrogen, with good product quality, avoiding the danger of oxidation, decomposition, combustion and explosion. This system can solve the organic solvent recovery, easy to oxidize and toxic materials drying problems, suitable for flammable, explosive and toxic cake-like, powdery materials and materials containing organic solvents drying and organic solvent recovery.

Closed-circuit rotary flash drying machine working principle

Before the system is used, nitrogen is used to replace the air in the system so that the oxygen content in the system reaches the safe concentration of solvent. The circulating nitrogen is heated by the heating equipment and then enters into the flash dryer. Wet material from the conveying device into the flash drying equipment screw charging mechanism, the screw charger can be frequency conversion speed regulation. The material is conveyed into the drying and crushing room by the spiral, then it is crushed by the blades with different angles and rotated at high speed, and then it is impacted by the high temperature airflow into the cyclone drying room with high speed, and entrapped and rises up, at this time, the temperature of the airflow decreases rapidly, and the moisture in the material is evaporated rapidly so as to complete the drying process. The oversized material is blocked by the amalgamation ring and falls to the drying and crushing room to continue crushing until the fine powder is obtained.

The dried material enters the cyclone separator with high speed and high temperature airflow, at this time, more than 90% of the material is separated and sunk into the collection bin, and the remaining small amount of material enters the bag filter with the airflow. Airflow from the outside of the bag into the filter, filtered and discharged upwards, in order to prevent the bag from accumulating material, by the mechanical blowback bag blowing, reducing nitrogen consumption, the material yield can reach more than 99.5%.

The tail gas enters into the multi-stage condenser (finned condenser with small pressure drop and good condensing effect) to condense the solvent inside the hot and humid gas. The condensed solvent is collected by a collection tank and stored (zero emission into the air, can be recycled). After condensation and dehumidification, the dry nitrogen gas is sent to the heater through the blower for recycling.

Closed-circuit rotary flash vaporization dryer performance characteristics

(1) This technology adopts rotary flash drying equipment, the material is refined due to centrifugal, shear, collision, and was highly dispersed state, the relative velocity between the gas-solid two phases is larger, strengthened mass and heat transfer; hot air in the drying chamber produces a strong rotary movement, the material on the wall produces a strong scouring effect, eliminating the phenomenon of sticky wall.

(2)The material drying time is short, which ensures the material quality.

(3) The system is fully enclosed structure, equipment filled with inert gas (such as nitrogen), in the drying of anaerobic materials or solvents containing flammable and explosive nature of the material, so that there is no oxygen in the gas, can not be combusted or oxidized, you can effectively avoid the equipment in the production of fire or explosion accidents, so rotary flash drying equipment is safer than ordinary equipment.

(4)The system is sealed with nitrogen for all moving equipments, and the oxygen analyzer is used to analyze the oxygen content of the system online, which improves the safety of the system.

(5) Due to the closed-circuit operation, there is no exhaust gas and dust discharged into the atmosphere, so it will not cause environmental pollution.

Closed-circuit rotary flash vaporization dryer process flow chart