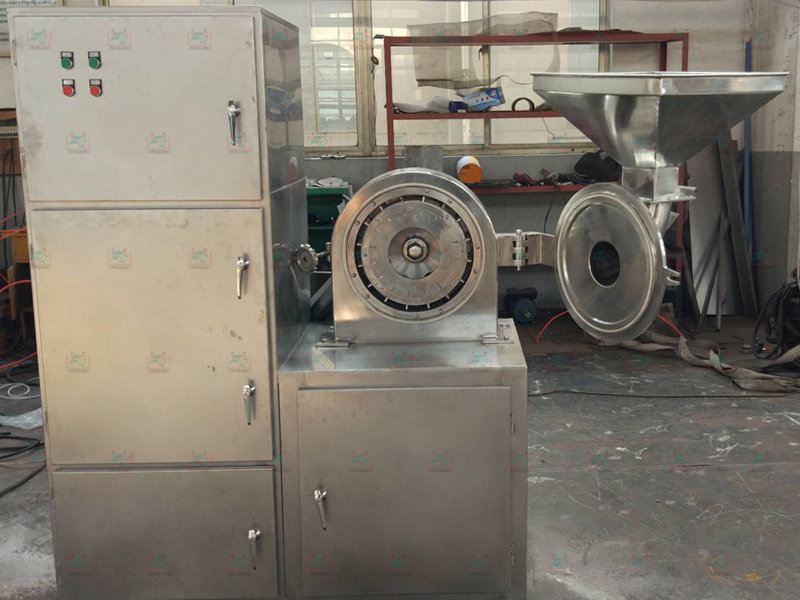

30B Series Universal High-Efficiency Pulverizer

Experience superior powder processing with our 30B Series Universal High-Efficiency Pulverizer. This industrial grinding machine is designed for high-speed, continuous operation, delivering fine and uniform powder for pharmaceutical, food, chemical, and herbal industries with integrated dust collection.

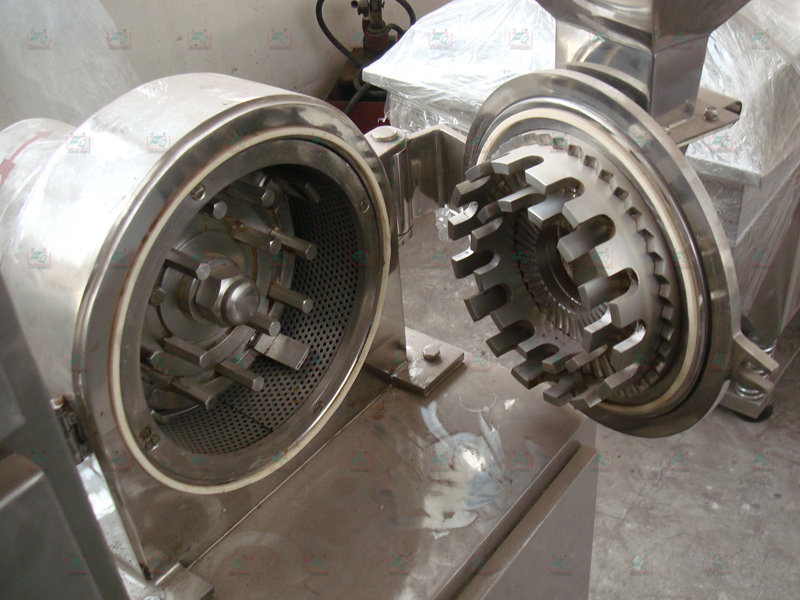

Working Principle of 30B Universal Pulverizer

Understand the robust and efficient grinding mechanism of our 30B Series High-Efficiency Pulverizer, ensuring optimal powder fineness and uniform particle size.

Advanced Technical Features of 30B High-Efficiency Pulverizer

Delivering superior performance through robust construction, precise grinding capabilities, and integrated dust management for efficient powder processing.

Robust Stainless Steel Construction

Manufactured from high-quality stainless steel (SS304/SS316L), ensuring durability, corrosion resistance, and compliance with GMP standards for pharmaceutical and food applications. This universal pulverizer is built to last.

Adjustable Fineness Control

Equipped with various screen sizes, allowing for precise control over the output powder fineness, ranging from 20 to 120 mesh. This industrial grinding machine adapts to diverse material requirements.

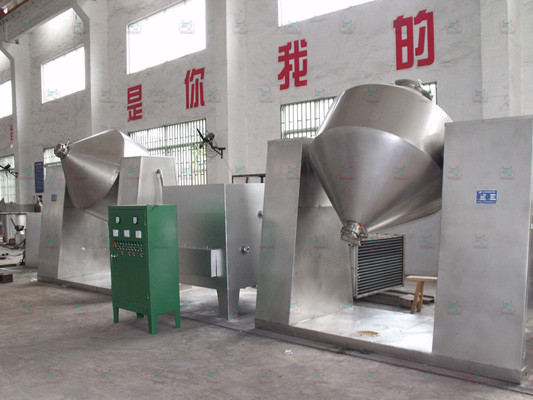

Integrated Dust Collection System

Features an efficient dust collection unit (e.g., cyclone separator and bag filter) to prevent dust flying during operation, ensuring a clean and safe working environment. Our pulverizer minimizes material loss.

Stable and Low Noise Operation

Designed with a stable structure and noise reduction features, providing smooth and quiet operation. The high-efficiency pulverizer ensures a comfortable working environment while maintaining high performance.

Easy Cleaning and Maintenance

Simple structure and accessible components facilitate quick and thorough cleaning, reducing downtime. This industrial pulverizer is designed for ease of maintenance, ensuring long-term reliability.

Versatile 30B Universal Pulverizer Applications

From pharmaceutical raw materials to food ingredients, our 30B Series industrial grinding machine delivers exceptional results across diverse industries.

Pharmaceutical Industry

Ideal for grinding Chinese herbal medicines, APIs, granules, and various pharmaceutical raw materials. Our pharmaceutical pulverizer ensures uniform fineness and meets stringent quality standards.

Food Processing

Perfect for grinding spices, coffee beans, sugar, grains, and other food ingredients. This food pulverizer helps achieve desired textures and enhances product quality and consistency.

Chemical Processing

Excellent for pulverizing chemical raw materials, pigments, resins, and various industrial powders. The chemical pulverizer provides efficient size reduction for diverse chemical applications.

Herbal & Agricultural

Superior for grinding dried herbs, agricultural products, and plant extracts. This universal grinder maintains the integrity of active compounds while producing fine powders for various uses.

Exceptional Value from 30B High-Efficiency Pulverizer

Maximize efficiency, product quality, and operational safety with our advanced industrial grinding machine.

Superior Powder Quality

The 30B universal pulverizer ensures uniform particle size distribution and high fineness, crucial for consistent product quality in pharmaceutical and food applications. Achieve optimal powder characteristics.

Enhanced Operational Efficiency

Designed for continuous and high-volume processing, this industrial grinding machine significantly boosts production throughput. The high-efficiency pulverizer reduces processing time and labor costs.

Improved Safety & Cleanliness

The integrated dust collection system minimizes airborne particles, creating a cleaner and safer working environment. This dust-free pulverizer protects operators and prevents cross-contamination.

Versatile & Cost-Effective

Its universal application across multiple industries makes it a versatile investment. The 30B pulverizer offers a cost-effective solution for various grinding needs, providing excellent return on investment.

Success Stories: 30B Universal Pulverizer in Action

Partnering with leading companies to achieve excellence in powder processing with our industrial grinding machine solutions.

Project Challenge:

The client needed a pharmaceutical pulverizer to grind various traditional Chinese herbal medicines to a fine, uniform powder while maintaining active ingredient integrity and meeting GMP standards.

Project Results:

• Achieved 100-mesh fineness for all herbs

• Maintained 98% active ingredient retention

• Increased processing capacity by 40%

• Fully compliant with GMP regulations

Project Challenge:

The facility required a food pulverizer to process various spices (e.g., cinnamon, turmeric) into fine powders, ensuring consistent texture, vibrant color, and rich aroma for their products.

Project Results:

• Produced uniform 80-mesh spice powder

• Enhanced color and aroma retention by 25%

• Reduced grinding time by 30%

• Increased daily output by 50%

Project Challenge:

The producer needed a chemical pulverizer to finely grind various pigments, requiring high efficiency and minimal dust generation to ensure product purity and a safe working environment.

Project Results:

• Achieved 120-mesh fineness for pigments

• Reduced dust emission by 90%

• Improved product purity by 15%

• Decreased energy consumption by 20%

Comprehensive Service Support for 30B Universal Pulverizer

From consultation to maintenance, ensuring optimal performance throughout your industrial grinding machine lifecycle.

Pulverizer Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial grinding machine design services tailored to your specific material properties and powder processing requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper universal pulverizer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your high-efficiency pulverizer. 24/7 technical support keeps operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve industrial pulverizer efficiency. Regular performance assessments ensure sustained optimal operation and compliance.