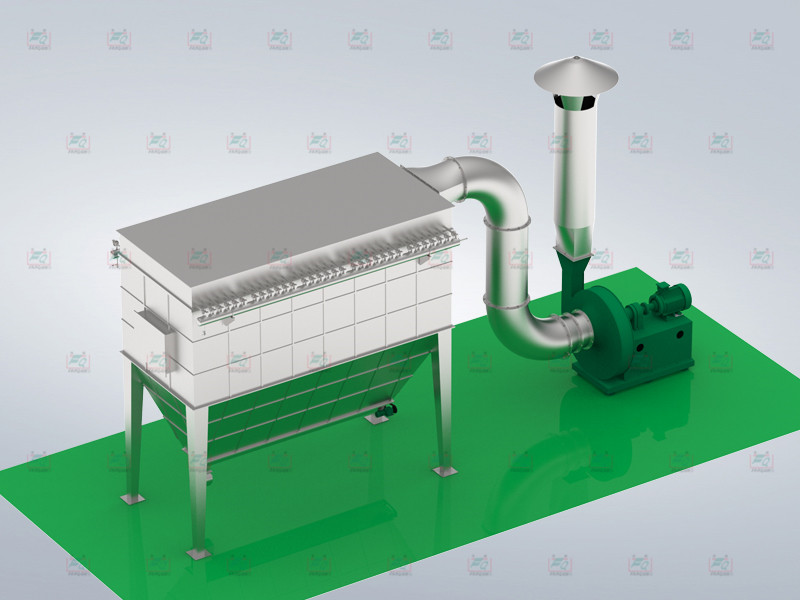

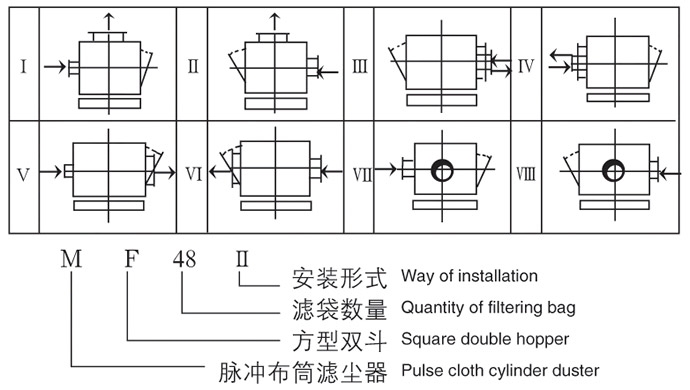

MF Series Pulse Bag Dust Catcher

Experience superior air filtration with our MF Series Pulse Bag Dust Catcher. This advanced industrial dust collector features pulse jet cleaning technology, delivering exceptional dust collection efficiency for pharmaceutical, chemical, food, and manufacturing industries with reliable operation and low maintenance.

Working Principle of MF Pulse Bag Dust Catcher

Understand the advanced pulse jet cleaning technology of our MF Series Industrial Dust Collector, ensuring optimal filtration efficiency and continuous operation.

Advanced Technical Features of MF Industrial Dust Collector

Delivering superior performance through innovative pulse jet technology, robust construction, and intelligent control systems for efficient dust collection.

Advanced Pulse Jet Cleaning System

Features high-performance pulse jet valves with precise timing control for effective filter bag cleaning. The pulse bag dust catcher ensures consistent filtration efficiency and extended filter bag life through optimized cleaning cycles.

High-Efficiency Filter Bags

Equipped with premium quality filter bags made from various materials (polyester, PTFE, aramid) to suit different applications. The industrial dust collector achieves >99.9% dust removal efficiency for particles down to submicron levels.

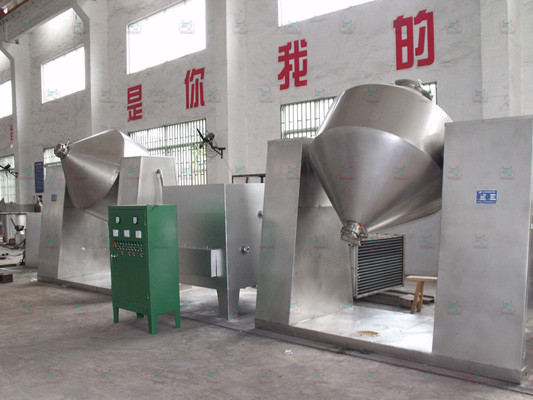

Robust Steel Construction

Manufactured from high-quality carbon steel or stainless steel with reinforced structure for durability. The baghouse dust collection system is designed to withstand harsh industrial environments and continuous operation.

Intelligent Control System

Features advanced PLC control with programmable cleaning cycles, differential pressure monitoring, and alarm systems. The bag dust collector provides automated operation and real-time performance monitoring for optimal efficiency.

Modular Design & Easy Maintenance

Modular construction allows for easy installation, expansion, and maintenance. The pulse bag dust catcher features accessible filter bag replacement, inspection doors, and simplified maintenance procedures to minimize downtime.

Versatile MF Pulse Bag Dust Catcher Applications

From pharmaceutical manufacturing to heavy industry, our MF Series industrial dust collector delivers exceptional air filtration across diverse applications.

Pharmaceutical Industry

Ideal for pharmaceutical manufacturing processes, API production, and tablet coating operations. Our pharmaceutical dust collector ensures GMP compliance and protects product quality from contamination.

Chemical Processing

Perfect for chemical powder handling, catalyst production, and pigment manufacturing. The chemical dust collector provides safe and efficient dust control for hazardous and non-hazardous materials.

Food Processing

Excellent for food powder processing, grain handling, and spice manufacturing. Our food-grade dust collector maintains hygiene standards and prevents cross-contamination in food production facilities.

Manufacturing Industries

Superior for metalworking, woodworking, cement production, and general manufacturing. The industrial dust collector improves workplace safety and environmental compliance across various manufacturing processes.

Exceptional Value from MF Industrial Dust Collector

Maximize operational efficiency, workplace safety, and environmental compliance with our advanced baghouse dust collection technology.

Enhanced Air Quality & Safety

The MF pulse bag dust catcher significantly improves workplace air quality by removing harmful dust particles. This industrial dust collector protects worker health and ensures compliance with occupational safety standards.

Cost-Effective Operation

Advanced pulse jet cleaning technology extends filter bag life and reduces maintenance costs. The bag dust collector provides excellent return on investment through energy efficiency and minimal operational expenses.

Reliable & Continuous Operation

Robust construction and intelligent control systems ensure reliable 24/7 operation. The baghouse dust collection system minimizes downtime and maintains consistent performance in demanding industrial environments.

Flexible & Scalable Solution

Modular design allows for easy customization and future expansion. The pulse bag dust catcher adapts to changing production requirements and can be configured for various industrial applications.

Success Stories: MF Pulse Bag Dust Catcher in Action

Partnering with leading companies to achieve excellence in industrial dust collection with our baghouse dust collection solutions.

Project Challenge:

The client needed an industrial dust collector for API production that could handle high-potency compounds while maintaining GMP compliance and protecting worker safety from hazardous dust exposure.

Project Results:

• Achieved 99.95% dust collection efficiency

• Maintained GMP compliance standards

• Reduced workplace dust levels by 98%

• Eliminated product cross-contamination

Project Challenge:

The facility required a bag dust collector for pigment production, handling fine particles with high dust loads while ensuring environmental compliance and maintaining product quality.

Project Results:

• Processed 50,000 m³/h of dusty air

• Achieved emission levels below 10 mg/m³

• Improved product quality by 30%

• Reduced maintenance costs by 40%

Project Challenge:

The company needed a food-grade pulse bag dust catcher for grain processing operations, requiring hygienic design, easy cleaning, and compliance with food safety regulations.

Project Results:

• Met all food safety standards

• Achieved 99.8% dust capture efficiency

• Reduced cleaning time by 50%

• Improved workplace air quality significantly

Comprehensive Service Support for MF Industrial Dust Collector

From consultation to maintenance, ensuring optimal performance throughout your baghouse dust collection system lifecycle.

Dust Collection System Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial dust collector design services tailored to your specific dust characteristics and air volume requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper pulse bag dust catcher setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your bag dust collector. 24/7 technical support keeps operations running smoothly.

Performance Optimization & Upgrades

Continuous performance optimization services and technology upgrades help improve baghouse dust collection efficiency. Regular assessments ensure sustained optimal operation and compliance.

Performance characteristics

In addition to the features of high dust removal efficiency, large handling air volume, stable performance and convenient operation and maintenance, Pulse Bag Dust Catcher also has the features of better use than type I, not easy to accumulate powder and wide range of applications.

Applicable materials

Pulse Bag Dust Catcher is widely used in ventilation and dust removal and dust recovery in grain and foodstuff, feed, metallurgy and chemical industry, building materials, medicine and other industries.