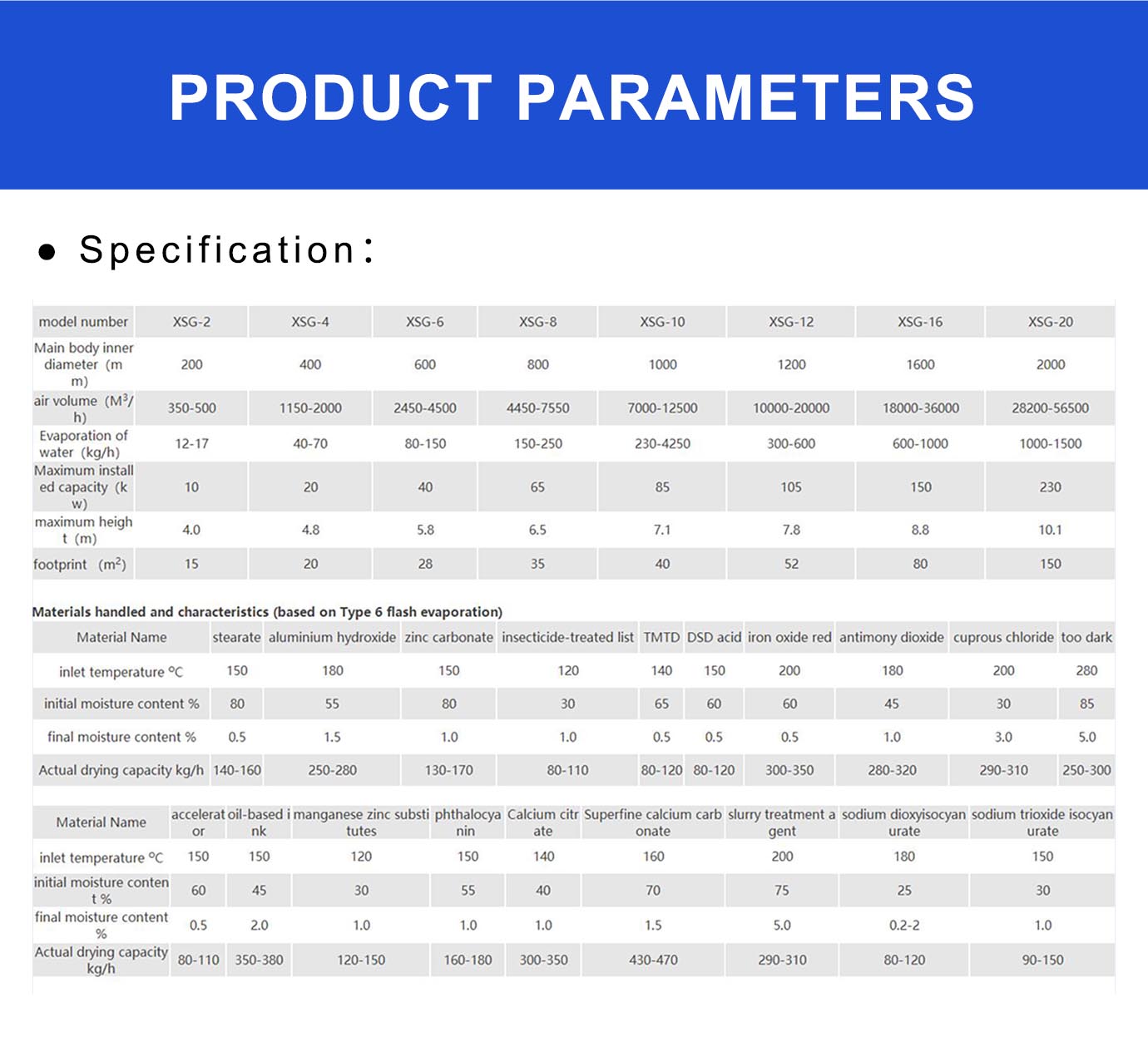

XSG Rotary Flash Dryer

Experience rapid and efficient drying with our advanced XSG Rotary Flash Dryer. Designed for paste materials, filter cakes, and heat-sensitive products, it delivers superior performance with energy efficiency and intelligent control.

Advanced Working Principle of XSG Rotary Flash Dryer

Discover the innovative technology behind our XSG Rotary Flash Dryer, ensuring optimal drying performance and product quality.

Exceptional Value for Your Operations

Maximize efficiency, quality, and profitability with our advanced flash drying technology.

Superior Product Quality

Achieves uniform drying with excellent particle size distribution and minimal thermal degradation. Short residence time preserves heat-sensitive materials while ensuring consistent moisture content and product specifications.

Enhanced Production Efficiency

Rapid drying process with high throughput capability enables continuous operation and increased productivity. Automated control systems reduce labor requirements and ensure consistent performance.

Cost-Effective Operation

Energy-efficient design reduces operating costs through optimized heat utilization and minimal product waste. Low maintenance requirements and robust construction ensure long-term reliability.

Flexible & Scalable Solutions

Available in multiple sizes to meet various production requirements. Customizable configurations allow for specific material handling needs and future capacity expansion.

Success Stories: XSG Rotary Flash Dryer in Action

Partnering with leading companies to achieve excellence in flash drying applications.

Project Challenge:

The client needed to dry heat-sensitive pharmaceutical intermediates with strict quality requirements, requiring precise temperature control and minimal thermal exposure while maintaining product purity.

Project Results:

• Product purity maintained at 99.9% with zero thermal degradation

• Drying time reduced from 8 hours to 30 seconds

• Energy consumption reduced by 45% compared to tray drying

• Successfully met FDA validation requirements

Project Challenge:

The client required efficient drying of catalyst filter cakes with high moisture content, demanding rapid processing while maintaining catalyst activity and preventing agglomeration.

Project Results:

• Catalyst activity retention rate reached 98%

• Production capacity increased by 300%

• Product uniformity improved significantly

• Operating costs reduced by 35% through energy efficiency

Project Challenge:

The client needed to dry modified starch paste while preserving functional properties, requiring gentle drying conditions and precise moisture control for food-grade applications.

Project Results:

• Functional properties preserved at 96% retention rate

• Moisture content achieved ±0.2% precision

• Production efficiency increased by 250%

• Successfully obtained food safety certifications

Comprehensive Service Support for Your XSG Rotary Flash Dryer

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Process Design

Our expert engineers provide comprehensive technical consultation and process design services tailored to your specific material properties and drying requirements, ensuring optimal performance and efficiency.

Professional Installation & Commissioning

Experienced installation team ensures proper equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity and safety from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your production running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing production needs. Regular performance assessments ensure sustained optimal operation.