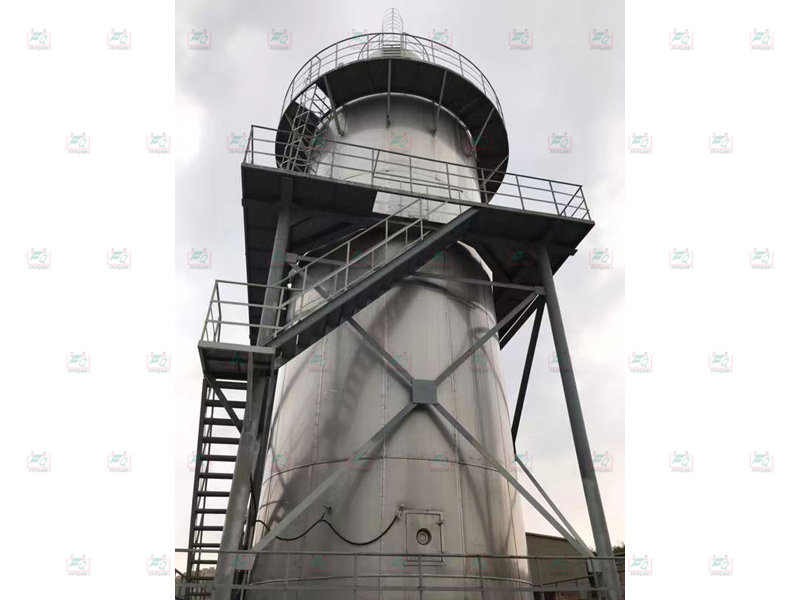

YPG Series Pressure Spray Dryer

Experience superior spray drying performance with our YPG Series Pressure Spray Dryer. This advanced industrial spray drying machine features high-pressure atomization technology, delivering exceptional drying and granulation efficiency for pharmaceutical, food, chemical, and detergent industries with reliable operation and precise control.

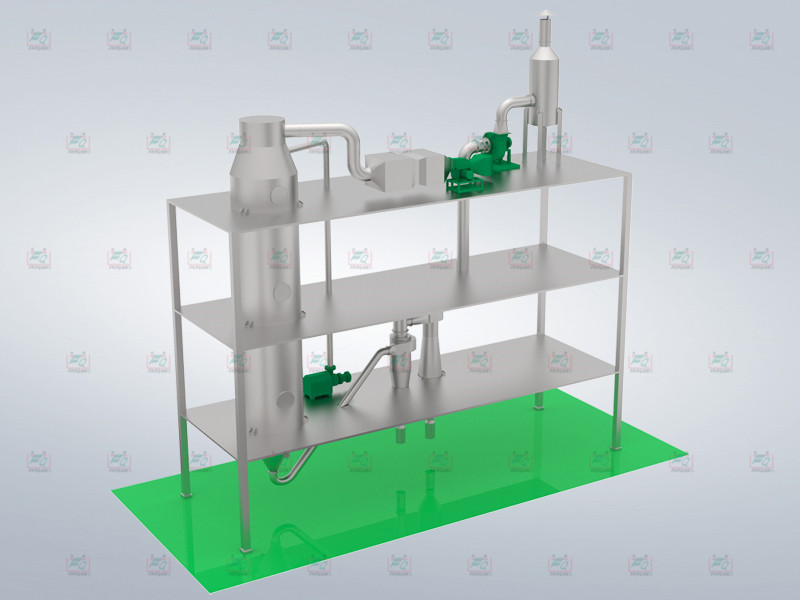

Working Principle of YPG Pressure Spray Dryer

Understand the advanced pressure atomization technology of our YPG Series Industrial Spray Drying Machine, ensuring optimal particle formation and efficient drying performance.

Advanced Technical Features of YPG Industrial Spray Drying Machine

Delivering superior performance through innovative pressure atomization technology, robust construction, and intelligent control systems for efficient spray drying operations.

High-Pressure Atomization System

Features advanced high-pressure pump and precision nozzles for optimal atomization. The pressure spray dryer achieves uniform droplet size distribution, ensuring consistent particle formation and superior product quality in spray drying applications.

Dual Function: Drying & Granulation

Combines drying and granulation in a single process, producing spherical particles with excellent flowability. The granulating spray dryer eliminates the need for separate granulation equipment, reducing processing costs and complexity.

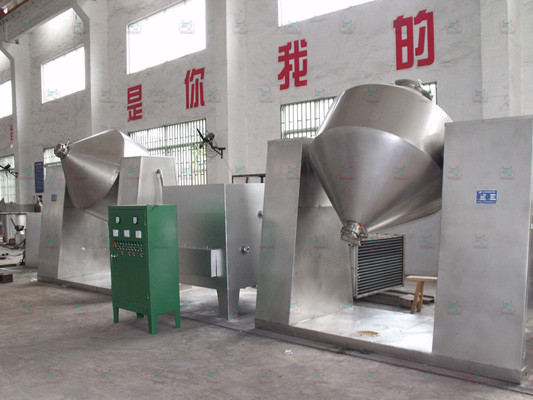

Robust Stainless Steel Construction

Manufactured from high-quality stainless steel (SS304/SS316L) with corrosion-resistant properties. The industrial spray drying machine is designed for continuous operation in demanding industrial environments with minimal maintenance requirements.

Advanced Temperature Control

Equipped with precise temperature control systems for inlet and outlet air temperatures. The spray drying equipment ensures optimal drying conditions while protecting heat-sensitive materials from thermal degradation.

Flexible Operation Parameters

Allows adjustment of pressure, flow rate, and nozzle size to accommodate different materials and product specifications. The pressure spray dryer equipment provides versatility for various industrial applications and production requirements.

Versatile YPG Pressure Spray Dryer Applications

From pharmaceutical formulations to food ingredients, our YPG Series industrial spray drying machine delivers exceptional results across diverse industries.

Pharmaceutical Industry

Ideal for pharmaceutical granulation, API processing, and tablet coating applications. Our pharmaceutical spray dryer ensures uniform particle size, excellent flowability, and compliance with GMP standards for drug manufacturing.

Food Processing

Perfect for instant powder production, milk powder processing, and food ingredient manufacturing. The food-grade spray drying equipment maintains nutritional value while producing high-quality powdered products.

Chemical Processing

Excellent for chemical powder production, catalyst preparation, and specialty chemical manufacturing. The chemical spray dryer provides precise control over particle characteristics and product purity.

Detergent Industry

Superior for detergent powder production, surfactant processing, and cleaning product manufacturing. The detergent spray dryer produces free-flowing granules with excellent dissolution properties.

Exceptional Value from YPG Industrial Spray Drying Machine

Maximize production efficiency, product quality, and operational flexibility with our advanced pressure spray dryer technology.

Superior Product Quality

The YPG pressure spray dryer produces uniform spherical particles with excellent flowability and dissolution properties. This industrial spray drying machine ensures consistent product quality and enhanced performance characteristics.

Enhanced Production Efficiency

Combines drying and granulation in a single step, significantly reducing processing time and energy consumption. The granulating spray dryer increases throughput while minimizing operational costs and complexity.

Flexible Processing Capabilities

Accommodates a wide range of materials from solutions to high-solid content slurries. The spray drying equipment adapts to various viscosities and concentrations, providing versatility for diverse applications.

Reliable & Continuous Operation

Robust construction and advanced control systems ensure reliable 24/7 operation. The pressure spray dryer equipment minimizes downtime and maintains consistent performance in demanding industrial environments.

Success Stories: YPG Pressure Spray Dryer in Action

Partnering with leading companies to achieve excellence in spray drying with our industrial spray drying machine solutions.

Project Challenge:

The client needed a pharmaceutical spray dryer for tablet granulation that could produce uniform granules with excellent compressibility while maintaining API stability and meeting regulatory requirements.

Project Results:

• Achieved 95% granule uniformity

• Improved tablet hardness by 30%

• Maintained 99% API stability

• Reduced processing time by 40%

Project Challenge:

The facility required a food-grade spray drying equipment for instant powder production, ensuring rapid dissolution, good flowability, and preservation of nutritional content.

Project Results:

• Achieved 3-second dissolution time

• Improved flowability by 50%

• Retained 95% nutritional value

• Increased production capacity by 60%

Project Challenge:

The company needed a detergent spray dryer for high-density powder production with excellent flowability, rapid dissolution, and consistent bulk density for packaging efficiency.

Project Results:

• Achieved 0.8 g/ml bulk density

• Improved dissolution rate by 45%

• Enhanced flowability significantly

• Reduced packaging costs by 25%

Comprehensive Service Support for YPG Industrial Spray Drying Machine

From consultation to maintenance, ensuring optimal performance throughout your pressure spray dryer equipment lifecycle.

Spray Drying Consultation & Design

Our expert engineers provide comprehensive technical consultation and custom industrial spray drying machine design services tailored to your specific material properties and production requirements.

Professional Installation & Commissioning

Experienced installation team ensures proper pressure spray dryer setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum efficiency from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime for your spray drying equipment. 24/7 technical support keeps operations running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve granulating spray dryer efficiency. Regular performance assessments ensure sustained optimal operation and compliance.