LPG Series High-speed Centrifugal Spray Drying Machine

Experience efficient and precise drying with our advanced LPG Series High-speed Centrifugal Spray Drying Machine. Designed for optimal powder quality across various industries, it offers superior performance, energy efficiency, and intelligent control.

Core Technology of LPG Series High-speed Centrifugal Spray Drying Machine

Explore the advanced process of our LPG Series spray drying equipment, ensuring optimal powder quality and production efficiency.

Advanced Technical Features of LPG Series Spray Dryer

Delivering superior performance through innovative technology and precision engineering

High-Speed Centrifugal Atomization Technology

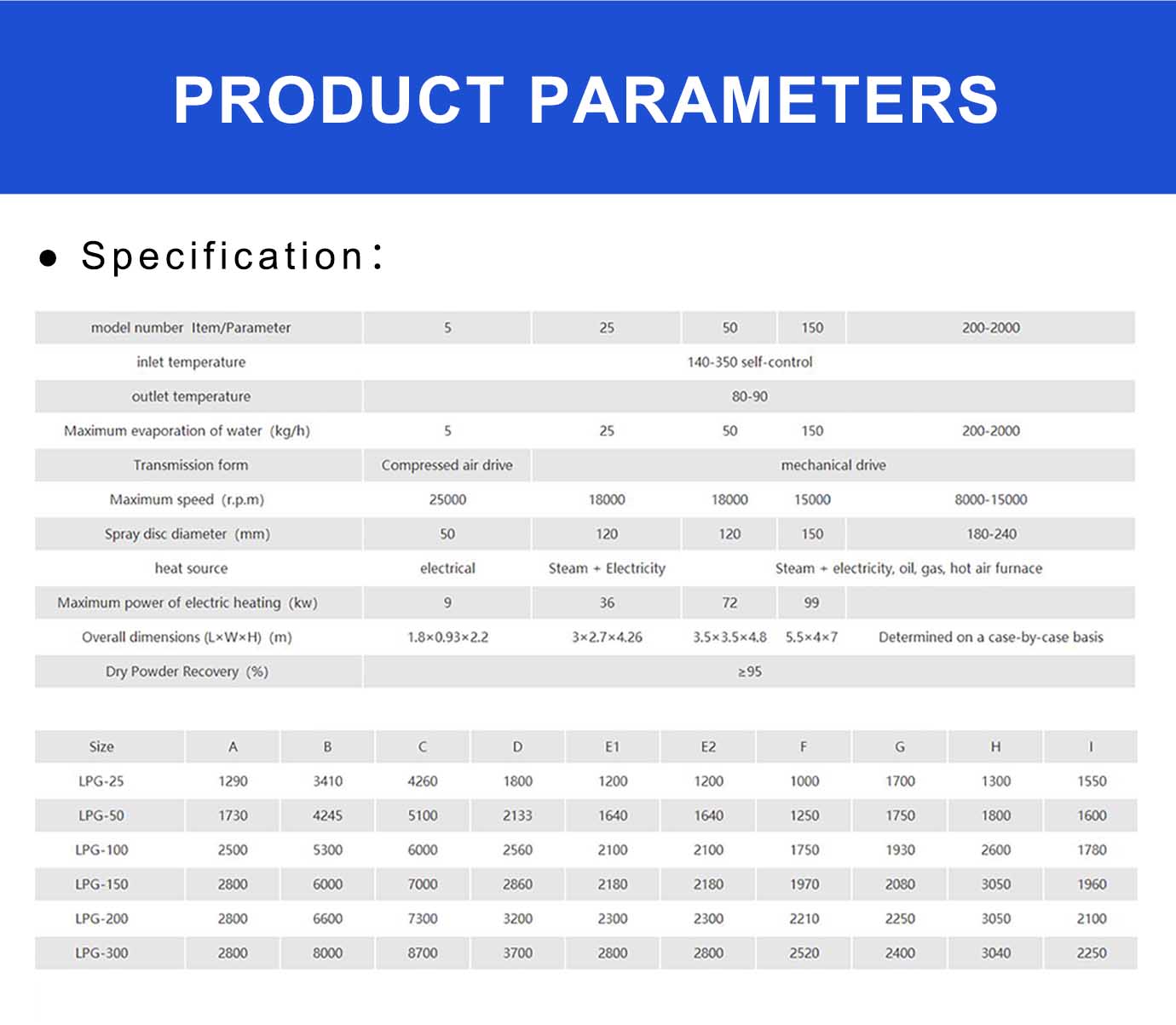

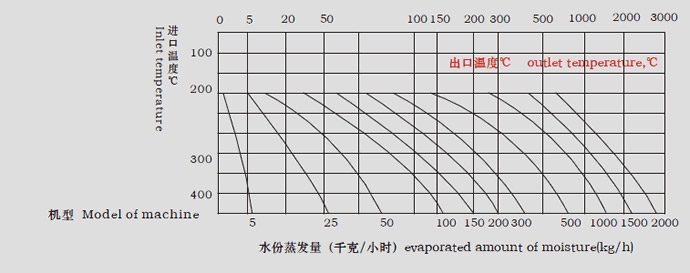

Features high-speed rotating disc (8,000-25,000 rpm) for uniform atomization, creating fine droplets with large surface area for rapid drying. The centrifugal force ensures consistent particle size distribution and optimal drying efficiency.

Precise Temperature Control System

Advanced PID control system maintains inlet temperature at 140-350°C and outlet temperature at 80-90°C, ensuring optimal drying conditions for heat-sensitive materials while preserving product quality and characteristics.

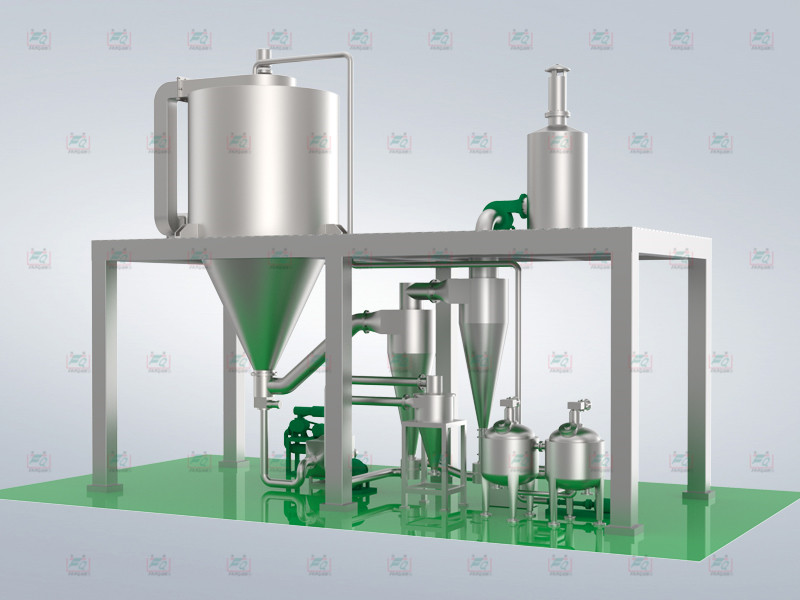

Efficient Powder Recovery System

High-efficiency cyclone separator achieves powder recovery rate ≥95%, minimizing product loss and maximizing yield. The system includes primary and secondary separation for optimal powder collection.

Versatile Heating Options

Multiple heating options including electricity, steam, gas, and oil fuel to meet different production requirements. Energy-efficient design reduces operating costs while maintaining consistent performance.

Hygienic Design & Easy Cleaning

Constructed with SUS304 stainless steel, featuring dead-angle-free design for easy cleaning and maintenance. Complies with GMP standards for pharmaceutical and food applications.

Versatile Applications Across Multiple Industries

From pharmaceuticals to food processing, our LPG Series spray dryer delivers exceptional results across diverse applications.

Pharmaceutical Industry

Ideal for drying pharmaceutical extracts, antibiotics, vitamins, and other heat-sensitive compounds. Ensures product purity and maintains active ingredient stability throughout the drying process.

Food & Beverage Processing

Perfect for producing instant coffee, milk powder, fruit juice powder, and food additives. Preserves nutritional value, flavor, and aroma while achieving desired powder characteristics.

Chemical Industry

Suitable for drying catalysts, detergents, dyes, and specialty chemicals. Handles various chemical solutions, emulsions, and suspensions with consistent quality output.

Biotechnology & Research

Excellent for laboratory-scale and pilot production of biological materials, enzymes, and research compounds. Provides precise control for experimental and development work.

Exceptional Value for Your Production Operations

Maximize efficiency, quality, and profitability with our advanced spray drying technology.

Superior Product Quality

Achieves uniform particle size distribution, excellent flowability, and high solubility. Powder recovery rate ≥95% ensures minimal product loss while maintaining consistent quality standards across all production batches.

Enhanced Production Efficiency

High-speed drying process with evaporation capacity from 5-2000 kg/h enables rapid production cycles. Continuous operation capability maximizes throughput and reduces production time significantly.

Cost-Effective Operation

Energy-efficient design reduces operating costs through optimized heat utilization and minimal product waste. Low maintenance requirements and durable construction ensure long-term cost savings.

Flexible & Scalable Solutions

Available in multiple sizes from laboratory scale (5 kg/h) to industrial scale (2000 kg/h). Customizable configurations meet specific production requirements and allow for future expansion.

Success Stories: LPG Series Spray Dryer in Action

Partnering with leading companies across industries to achieve excellence in powder production.

Project Challenge:

The client needed to produce high-purity antibiotic powder with strict quality requirements, requiring precise temperature control and contamination prevention while maintaining active ingredient stability.

Project Results:

• Product purity achieved 99.8%, exceeding pharmaceutical standards

• Zero contamination incidents with GMP-compliant design

• Production efficiency increased by 40% compared to previous method

• Successfully passed FDA inspection and regulatory approval

Project Challenge:

The client required high-quality instant coffee powder production with preserved aroma and flavor, demanding precise drying conditions and consistent particle size for optimal solubility.

Project Results:

• Aroma retention rate reached 95%, superior market feedback

• Particle size uniformity improved by 35%

• Solubility time reduced to under 3 seconds

• Annual production capacity increased by 60%

Project Challenge:

The client needed to process various chemical solutions with different viscosities and properties, requiring flexible operation parameters and consistent quality output across multiple product lines.

Project Results:

• Successfully processed 15 different chemical formulations

• Product changeover time reduced to 30 minutes

• Quality consistency improved by 50% across all products

• Operating costs reduced by 25% through energy efficiency

Comprehensive Service Support for Your LPG Series Spray Dryer

From consultation to maintenance, ensuring optimal performance throughout the equipment lifecycle.

Technical Consultation & Custom Design

Our expert engineers provide comprehensive technical consultation and custom design solutions tailored to your specific material properties and production requirements, ensuring optimal performance and efficiency.

Professional Installation & Commissioning

Experienced installation team ensures proper equipment setup and commissioning. Comprehensive operator training programs enable your team to achieve maximum productivity from day one.

Preventive Maintenance & Spare Parts

Proactive maintenance programs and readily available genuine spare parts ensure minimal downtime. 24/7 technical support and rapid response service keep your production running smoothly.

Process Optimization & Upgrades

Continuous process optimization services and technology upgrades help improve efficiency and adapt to changing production needs. Regular performance assessments ensure sustained optimal operation.